In demanding industrial sectors such as mechanical engineering, energy, e-mobility, automotive and defense, the reliability of welded joints is crucial. Welding quality control covers all the checks required to ensure that a welded joint meets mechanical, dimensional and safety requirements.

These checks identify defects, discontinuities or anomalies before commissioning, ensuring the durability, safety and regulatory compliance of parts. Good quality control combines visual, destructive and non-destructive methods with rigorous documentation and traceability of operations. It is an essential pillar of process control, whether for laser welding or additive manufacturing.

Why quality control is essential in welding

The importance of weld quality control is not limited to final assembly validation. It applies to several fundamental industrial issues:

- Safety and reliability: a faulty weld can compromise the integrity of a system, particularly under stress, pressure or fatigue.

- Durability of parts: checking for cracks, porosity, lack of fusion or inclusion helps guarantee longevity.

- Compliance with regulations and standards: many sectors require inspections to certify the quality of welds.

- Cost reduction: early detection of a defect avoids scrap, production stoppages, rework or re-compliance.

- Traceability and quality assurance: documenting processes and inspections is essential for audits, certifications and guarantees.

This type of approach is all the more necessary when using advanced technologies such as laser welding, which requires appropriate controls.

Destructive and non-destructive methods for quality control of welds

Non-destructive testing (NDT)

The most common choice for inspecting the quality of a weld without damaging the part is Non-Destructive Testing (NDT). These methods can detect visible or internal defects while keeping the part intact. Among the most widespread techniques :

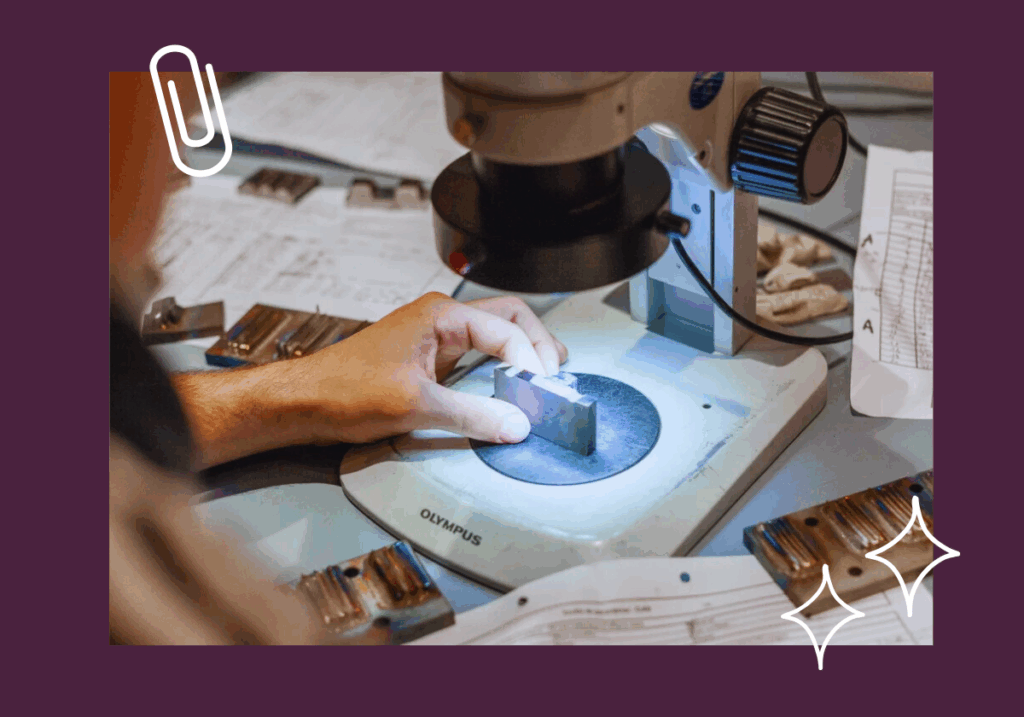

- Visual inspection (VT – Visual Testing): the first level of control, useful for detecting surface defects (cracks, porosity, irregularities).

- Penetrant Testing (PT): useful for identifying open surface cracks by penetration of a colored liquid.

- Magnetoscopy (MT – Magnetic Particle Testing): for ferromagnetic materials, to reveal cracks or discontinuities close to the surface.

- Ultrasound (UT – Ultrasonic Testing): high-frequency acoustic waves are sent to detect internal defects (cracks, inclusions, porosity).

- Radiography / radioscopy (RT): use of X-rays or gamma rays to visualize the inside of the weld and spot defects invisible to the naked eye.

These methods can be combined according to the criticality of the weld, the end use of the part, and the normative requirements.

When is destructive testing used?

Certain validations, especially for qualification or certification purposes, or for a test batch, may require destructive testing (tensile, bending, macrography, etc.) to assess mechanical properties and metallurgical structure. However, these tests are reserved for samples or test series, as they involve the destruction of the part under test.

Special features of laser welding quality control and high-performance processes

Laser welding, with its high precision, low heat-affected zone and ability to assemble complex geometries, requires appropriate controls. Potential defects can vary: lack of fusion, porosity, inclusion, invisible surface cracks, thermal expansion, etc.

As a result, the inspection of laser-processed assemblies often requires :

- In-depth NDT methods

- Rigorous documentation of welding parameters

- Traceability of operations

- Post-processing analysis (dimensional control, heat treatment, mechanical testing).

What’s more, in a context where laser welding is integrated for new or repaired parts, the initial quality of metal deposits and the consistency of assemblies require equally rigorous controls. Quality controllers can rely on process histories, material certificates and manufacturing traceability.

How DOUBLE CŒUR guarantees the quality of welds and assemblies

As a specialist in laser processes, DOUBLE CŒUR integrates welding quality control into all its processes. As soon as the project is signed, a protocol is put in place: preparation of parts, choice of appropriate welding methods, machine parameterization. Before delivery, all parts undergo non-destructive testing (visual, ultrasonic or radioscopic, as appropriate), and are fully traceable (welding history, materials, certificates, inspection report). In the event of a defect, the part is either brought back into conformity or rejected, thus guaranteeing that assemblies comply with the most stringent requirements.

When required by the project, DOUBLE CŒUR can also carry out destructive testing on samples to validate mechanical strength and fatigue resistance, particularly for critical applications.

This rigorous approach ensures consistent quality, reduces rejects and guarantees the “second life” of repaired or assembled parts – a particularly relevant argument for customers committed to cost optimization and sustainability.

Welding quality control is an essential step in any assembly or repair process, whether laser welding or processes linked to additive manufacturing. By combining appropriate methods (NDT, visual inspections, destructive spot checks), rigorous traceability and technical expertise, it guarantees the reliability, safety and durability of parts. As an expert player, DOUBLE CŒUR integrates this quality assurance approach into each and every one of its projects, guaranteeing its customers compliant, durable and optimized assemblies.