LASER WELDING

Presentation

Laser welding subcontracting: entrust your production to us

Our subcontracting department is able to meet companies’ needs for small, medium and large production runs in a wide range of sectors.

Whether for prototypes or production runs, we can take charge of the development and production of your parts, reducing your industrialization lead times. We can produce your parts while you are acquiring dedicated laser equipment, or during critical processes.

Our equipment

The TruDisk dual-core fiber laser disk

The TruDisk disc laser is a high-performance laser for welding workpieces up to large dimensions. It combines high power with maximum beam quality for our customers’ work.

The quality of the sensor data, monitoring all important laser parameters, ensures optimum quality as part of our Industrie 4.0 policy.

Laser welding robot with turntable 1.2 m

Fiber lasers up to 12kW power

Manual welding

1.5 kW

Control laboratory

Precision welding

Large parts

Complex 2D or 3D shapes

No excess weld metal

Technology

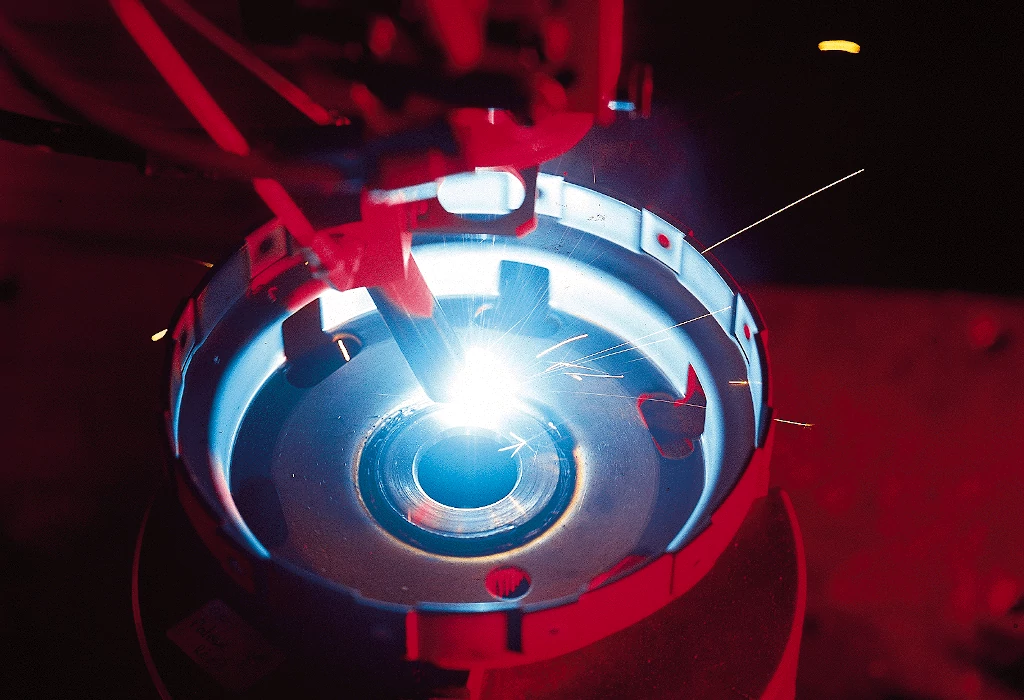

The BrightLine technology fiber-disc laser from Trumpf

Our laser welding machines use Trumpf’s BrightLine technology. They enable precision welding of complex 2D or 3D shapes, with or without the filler of material, with high quality, precision and large dimensions.

The laser beam enables narrow, deep and fast welding. The resulting parts have no excess thickness, and are tested to meet predefined specifications.

Read more

Laser welding meets every challenge

The challenge of material ejection in laser welding

Hardly any other tool is as versatile as the laser, even for producing deep welds several meters long.

For deep welding, very high power densities of around 1 megawatt per square centimeter are required.

This can lead to spattering under certain circumstances due to the high heat input and steam formation.

The quality of the weld bead may suffer, and time-consuming and costly manual rework may be indispensable.

With BrightLine Weld, we have the solution.

Why do material ejections occur in deep welding?

The laser beam heats the material until it evaporates. The escaping metal vapour sets the melt in motion and accelerates it.

If the acceleration of the melt is too high, particles of material detach from the back of the melt.

Ejections into the weld bead also occur, leaving less material available to form the weld bead.

The positive effects of BrightLine on the welding result and the welding process

It’s not just the quality of the weld that’s preserved. There are also no more ejections of material sticking to the component itself. Machine downtime and scrap rates are drastically reduced, and weld quality is improved. Thanks to BrightLine and our know-how, we can weld materials such as structural steel, stainless steels or even copper and aluminum alloys virtually flawlessly.

BrightLine optical fiber contains an inner and outer fiber core, enabling the laser power to be distributed flexibly according to the material. Power distribution can thus be optimally adjusted to the desired result.

An additional ring beam enlarges the opening of the steam passage, allowing metal steam to escape more easily. The melt precipitated towards the surface is now deflected by the ring beam towards the melt bath, and no splashing occurs.

We also carry out the necessary statistical controls, such as leak testing, mechanical strength and corrosion resistance tests, as well as all the metallurgical analyses required to qualify our welding processes.

Prototypes

Production of custom parts (prototypes, qualification parts, blanks, etc.)

Preseries

Manufacture of parts or sub-assemblies (ramp-up, load shedding, production safety, etc.)

Productions

Series production to confirm the robustness of a new process (qualification, robustness, single reference, small series, etc.).

Application areas

All industrial fields

Aeronautics

Spatial

Nuclear

Energy

Automotive

Rail

Contact

A team of laser experts at your service

Contact us today to benefit from expert advice, impeccable service quality and an industrial partnership tailored to your needs.

Together, we can make your most ambitious projects a reality.