At DOUBLE CŒUR, we place traceability at the heart of our metal additive manufacturing and laser welding processes. This strategic choice meets a growing demand from manufacturers to produce complex, reliable, standards-compliant parts, while ensuring total transparency at every stage of the production cycle.

Why is traceability crucial in additive manufacturing?

In sectors such as aerospace, energy, rail and defense, laser technology is used to produce complex geometries and unique parts. But without rigorous traceability, it’s impossible to guarantee material quality, repeatability or regulatory compliance.

Our commitments:

- Identify each part as soon as it is digitally created

- Monitor the entire manufacturing process (machine parameters, materials, temperature, speed, etc.).

- Record production data for each batch

- Facilitate quality audits and customer controls

Our tools for complete traceability

We have set up an advanced traceability ecosystem, integrated into our industrial platform.

Key tools used in our workshops :

- Connected database: every critical parameter is logged and centralized

- Barcode and QR code readers: for individual part tracking

- Laser beam analysis: continuous monitoring of parameters during material melting

- OCT (Optical Coherence Tomography): non-destructive in-process inspection

Thanks to these technologies, each part has a complete, searchable and verifiable history.

Integrated quality control

Traceability alone is not enough: it must be coupled with a rigorous quality approach. At DOUBLE CŒUR, we have structured a quality system:

- Systematic calibration before each production run

- In-line and post-process control (geometry, density, metallurgy)

- Statistical data analysis (box plot, Pareto, etc.)

- Proactive non-conformity management with the 8D method

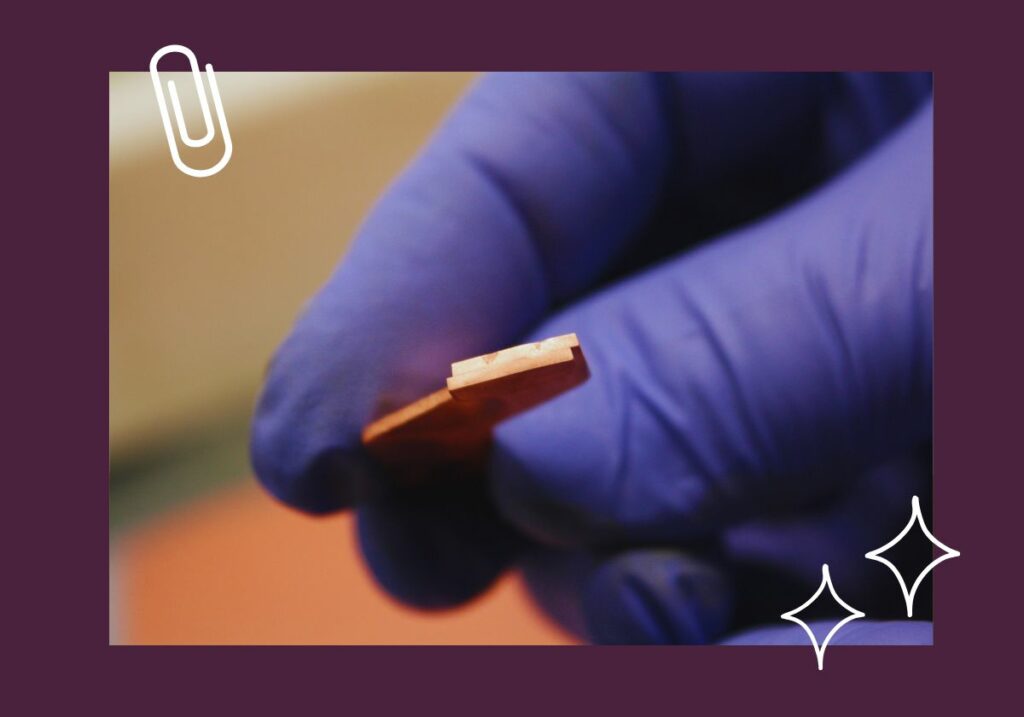

Concrete results for critical parts

Our approach is bearing fruit:

- More than 1,200 aeronautical parts laser-refurbished without defects

- 60,000 electronic components produced with full traceability

- 193,000 compliant battery module welds

These results illustrate our ability to master both laser processes and industrial traceability requirements.

DOUBLE CŒUR, your partner for traceable and reliable additive manufacturing

Our mission is clear: to support manufacturers from design to series production with tailor-made, reliable and traceable solutions, based on advanced technologies and proven know-how.

Looking to secure your production?

Contact our experts for personalized support.