Our industrial equipment for laser welding and additive manufacturing

Our high-performance laser welding and additive manufacturing equipment

DOUBLE CŒUR has a state-of-the-art industrial platform designed for additive metal manufacturing and high-precision laser welding.

Our facilities include :

- Latest-generation DED machines (wire and powder)

- High-power industrial lasers (up to 10 kW)

- Multi-axis robot cells (up to 15 axes)

- On-line quality control and metallurgical analysis systems

This infrastructure guarantees reliable, repeatable production, for complex metal parts, whether one-off or in small series.

An advanced industrial platform

This platform ensures reliable, consistent and compliant production, even for complex projects. We are also equipped with the first robotized machine to incorporate AMFREE technology, ideal for parts up to 5 m in length and 30 m³ in volume.

An integrated production chain

Our chain covers design, simulation, process control, non-destructive testing and metallurgical characterization, with a wide range of materials (stainless steel, aluminum, titanium, copper, etc.).

Thanks to this infrastructure, DOUBLE CŒUR is the industrial partner of reference for your laser welding and additive manufacturing needs, even on a large scale, with a high level of quality, precision and responsiveness.

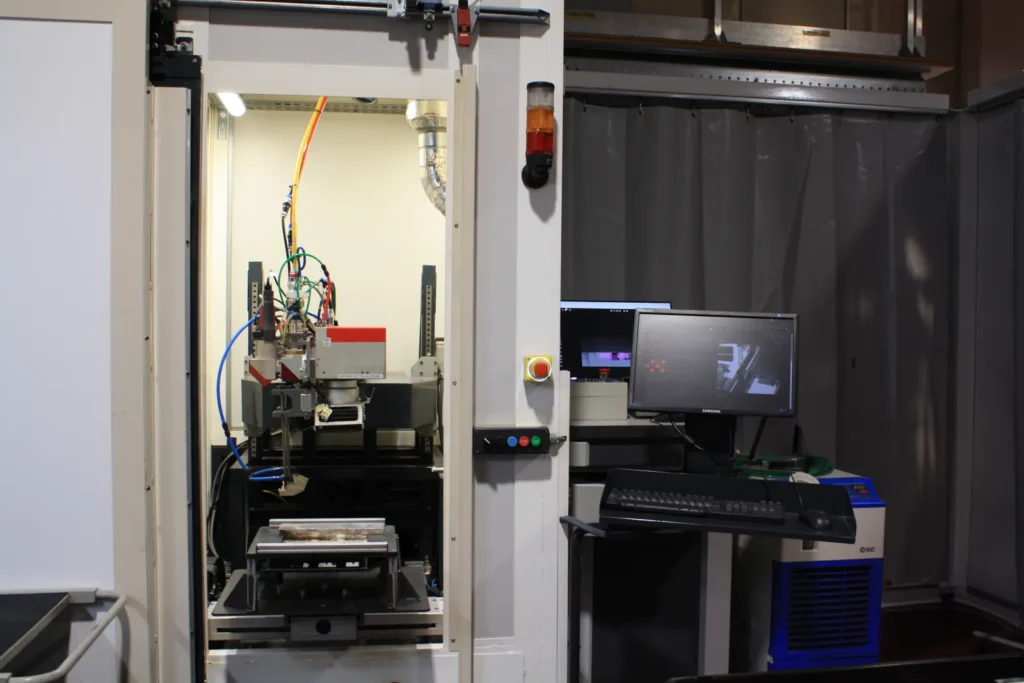

5-axis powder laser DED: manufacturing complex parts with metal additive manufacturing

Designed for additive manufacturing of high-precision metal parts, this 5-axis DED powder laser center enables multi-oriented deposits with a meticulous finish and optimum material density.

Thanks to its controlled environment (inert atmosphere), it is suitable for sensitive alloys such as titanium, Inconel and aluminum.

This equipment is strategic for demanding sectors such as aeronautics, energy and defense.

Technical data

Laser power

Laser melting up to 6 kW

Part dimensions

Up to 800 mm height and 600 mm diameter

Load capacity

Up to 300 kg

Targeted applications

Localized production, repair or functional addition

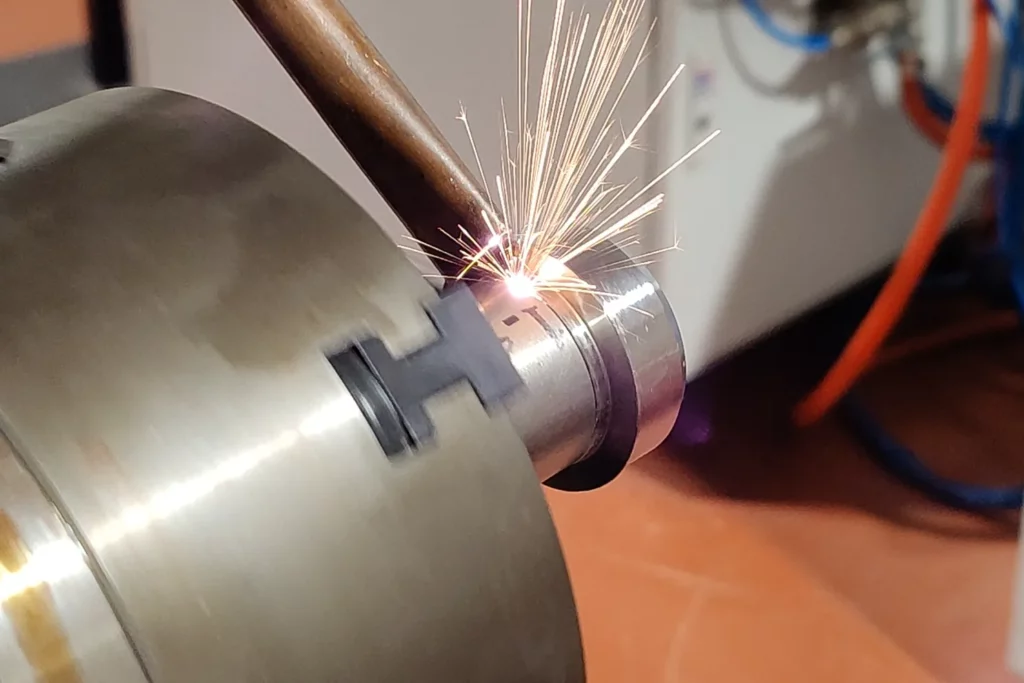

High-precision industrial laser welding for reliable, durable assemblies

Thanks to our 3-axis NC center dedicated to industrial laser welding, we guarantee precise, homogeneous and resistant metal assemblies, even on multi-material parts.

This welding system integrates a high-power laser and X, Y, Z digital control for fine control of material fusion. Thermal control reduces distortion, ensuring weld bead repeatability, even on complex parts.

This center is particularly well suited to critical parts requiring high mechanical strength, consistent metallurgical quality and controlled mass production.

Technical data

Laser power

Laser melting up to 6 kW

Part dimensions

Up to 700 mm diameter and 400 mm height

Load capacity

Up to 80 kg

Targeted applications

Critical assembly, multi-material welding, series production

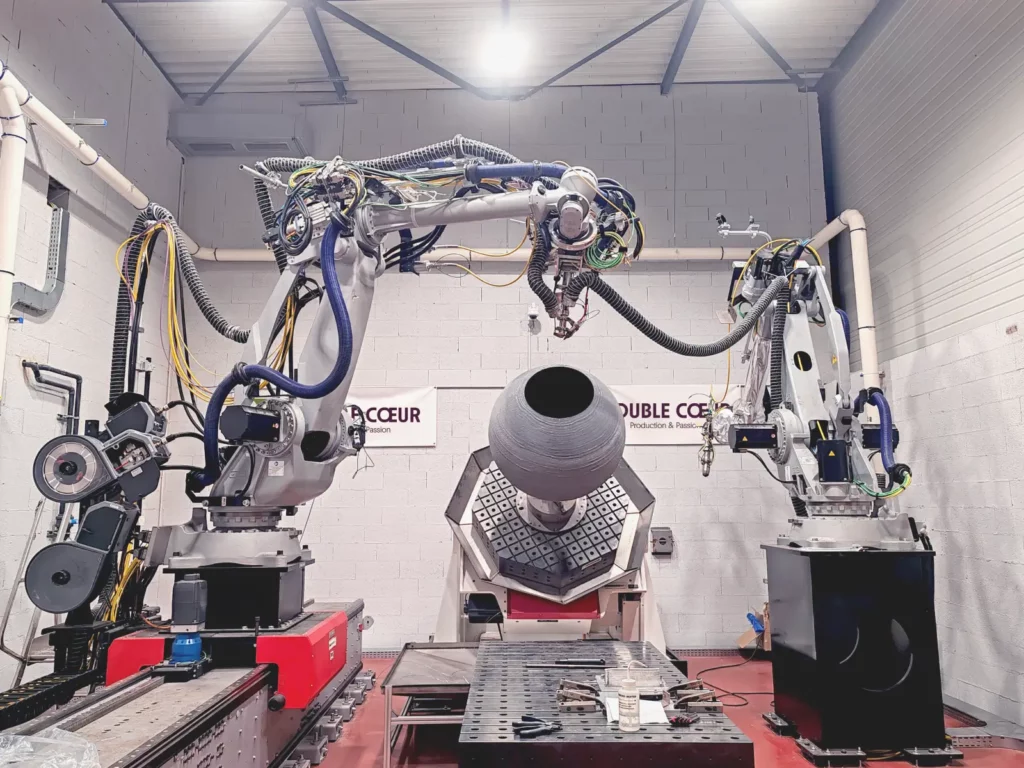

Production of large multi-technology, multi-material metal parts

This 15-axis robotic cell combines two synchronized robots with a high-capacity turning device, offering optimum flexibility for the processing of very large industrial metal parts. It integrates three advanced processes: wire laser DED, powder laser DED and laser welding, covering a wide range of needs from material deposition to complex assembly.

Thanks to a laser of up to 10 kW, it enables fast, precise deposits on components up to 5 m long, 2.5 m in diameter and 5 tons, while guaranteeing consistent metallurgical quality.

A strategic solution for the energy, naval, rail, space and defense sectors.

Technical data

Laser power

Up to 10 kW

Part dimensions

Up to 5 m long and 2.5 m in diameter

Load capacity

Up to 5 tons

Targeted applications

XXL manufacturing, heavy repairs, complex multi-material assemblies

A solution for large critical parts

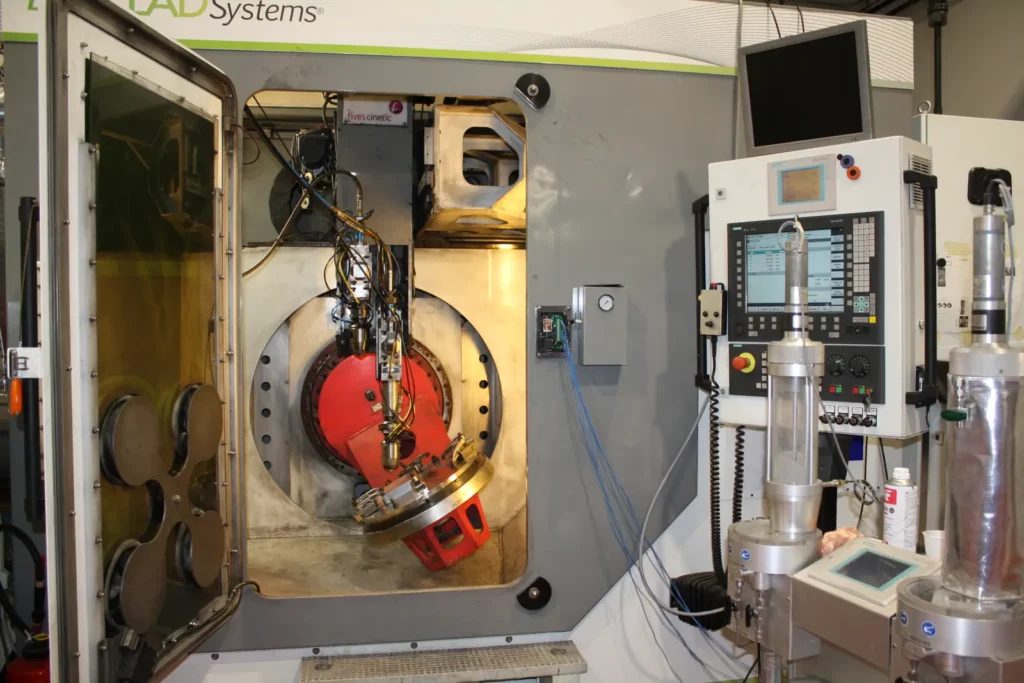

This 9-axis robotized cell combines a high-capacity robot and a Siemens numerical control, for precise trajectories on very large metal parts. Versatile, it integrates both the DED laser powder process and laser welding, to manufacture, repair or modify complex industrial components.

Its 6 kW laser enables stable, controlled deposits, even on sensitive or multi-material surfaces. It guarantees excellent mechanical resistance, even on highly complex geometries.

A strategic asset for the energy, naval, rail and defense sectors.

Technical data

Laser power

Up to 6 kW

Part dimensions

Up to 5 m long and 2.5 m in diameter

Load capacity

Up to 5 tons

Targeted applications

Complex fabrication, localized repairs, welding of large structures

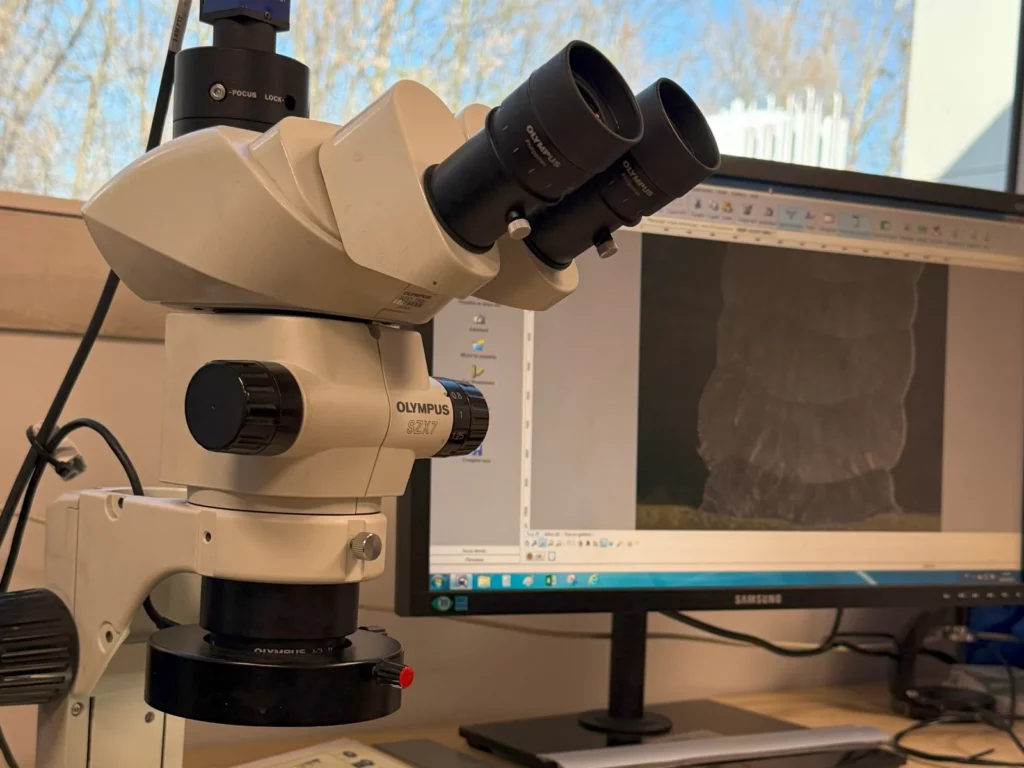

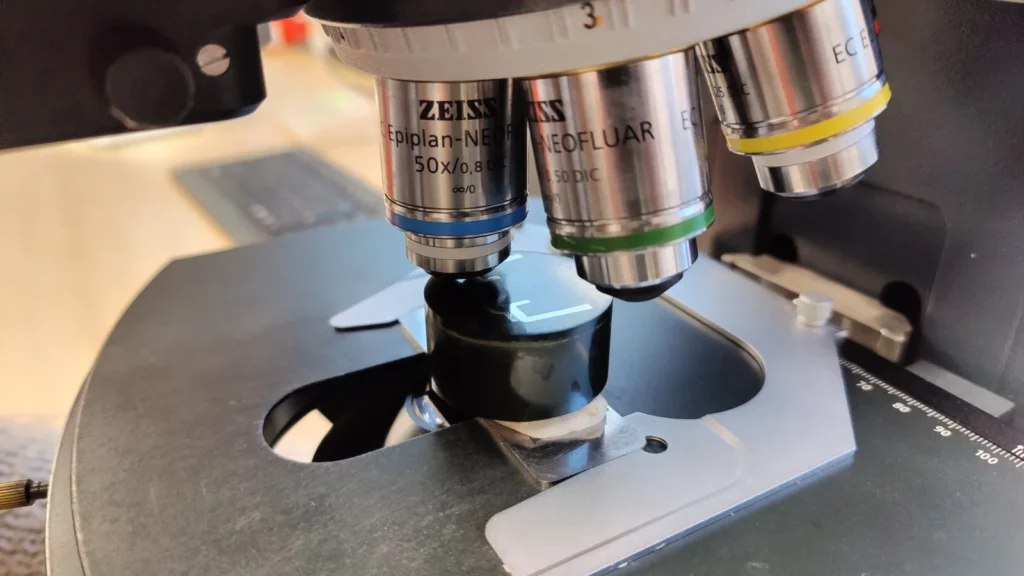

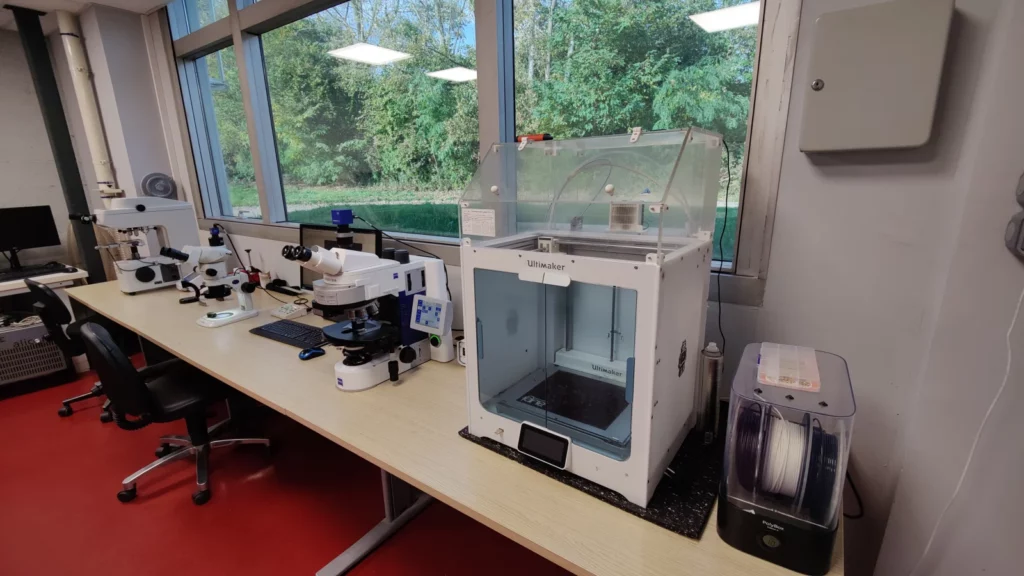

Production-integrated metallurgical and dimensional quality controls

Our two laboratories, metallographic and observation, ensure the quality, conformity and performance of the parts we produce. We carry out comprehensive checks: geometry, dimensional measurements, laser welding quality, material health and validation according to your specifications.

Key equipment: optical microscope, binocular magnifier, traction machine, FARO arm, micro durometer, dye penetrant inspection, automatic cut-off machine, coating machine (hot and cold), automatic polisher, chemical attack hood, etc.

Complete mastery of quality control, integrated into our industrial production chain.

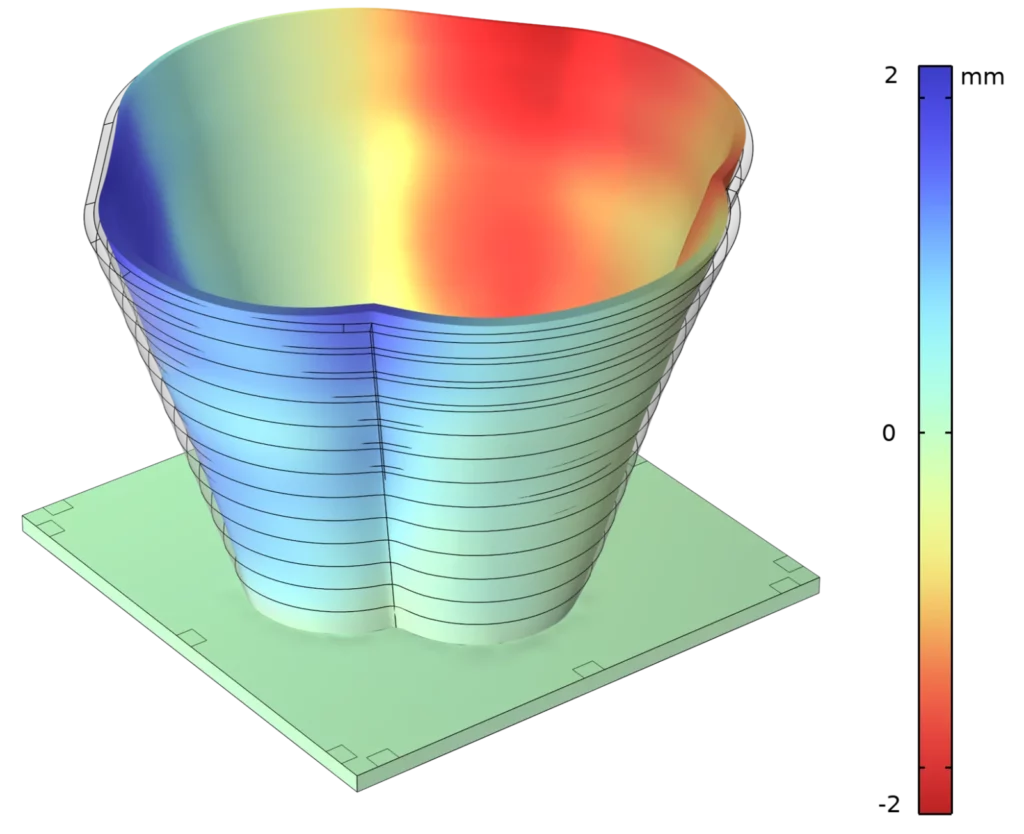

Thermomechanical & hydrodynamic simulation: success from the very first part

We integrate digital simulation into our manufacturing processes to optimize settings, improve performance and reduce iterations.

In additive manufacturing, our thermomechanical simulation tools enable us to anticipate residual deformations and stresses throughout the part, so that we can produce it right the first time.

In laser welding, thermo-hydrodynamic modeling helps us to reach a stabilized regime more quickly, with fewer physical tests.

The result: faster technical adjustments, controlled quality and excellent repeatability.