Outsourcing a medium-volume laser welding operation has become a strategic lever for manufacturers seeking both technical performance and cost control. This production format, situated between a single part and a mass production run, demands agile organization, rigorous quality control and perfect assembly repeatability.

Calling on a laser welding subcontractor for medium production runs meets several objectives:

- Reduce production lead times without mobilizing an in-house line

- Consistent quality on intermediate volumes

- Avoid investment costs in specialized equipment

- Maintain flexibility in response to fluctuations in demand

DOUBLE CŒUR offers medium-volume laser welding subcontracting, perfectly adapted to the needs of manufacturers in sectors such as mechanical engineering, energy, automotive, e-mobility and defense.

Why choose subcontracting for your medium production runs in laser welding?

Subcontracted medium-volume laser welding meets the needs of companies that don’t have the capacity or interest to bring the process in-house, while still producing regular volumes. This choice combines assembly quality, controlled production rates and reduced technical constraints.

Entrusting your operations to a partner specialized in medium-volume laser welding allows you to :

- Produce parts in intermediate quantities (tens to thousands) with a high level of repeatability.

- Avoid heavy investment in robotized cells or industrial lasers.

- Rely on an expert capable of fine-tuning the process according to the geometry, alloy or complexity of the parts.

This industrial subcontracting model also ensures a gradual ramp-up, ideal for pre-production or product launches.

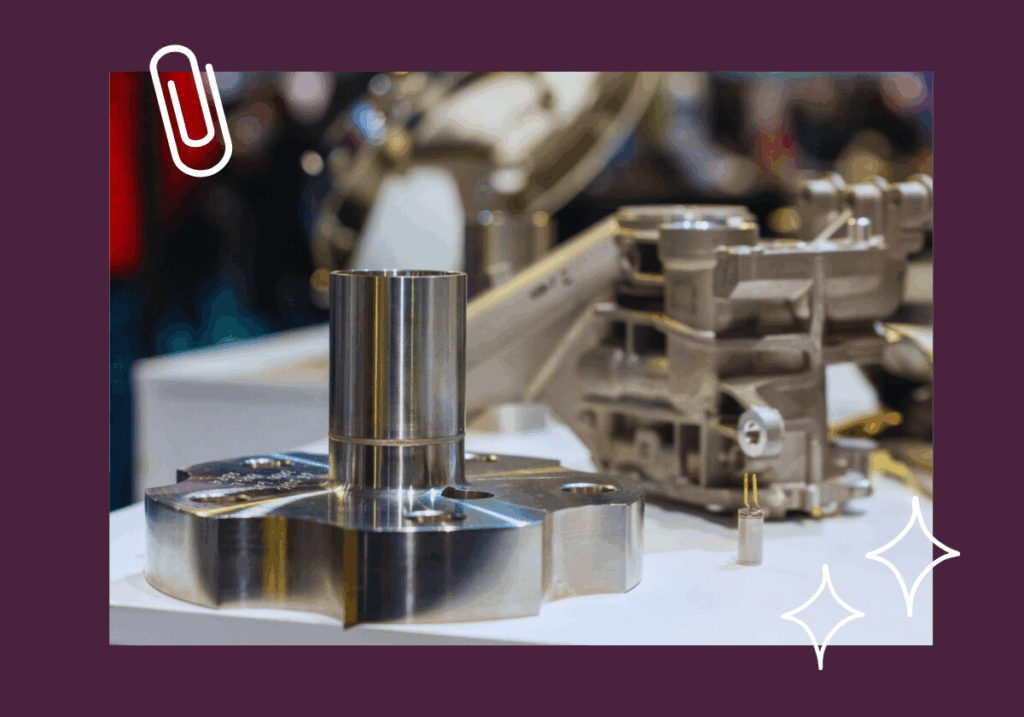

The specifics of laser welding for medium-volume production

Medium-volume production requires a balance between precision, speed and consistency. This is precisely what laser welding provides, a process that is particularly well-suited to this industrial format.

A process perfectly suited to technical series

Medium-volume laser welding is ideal for complex parts requiring flawless assembly. Thanks to its fine focus, it guarantees :

- A small heat-affected zone

- Precise welding even on small parts

- Excellent compatibility with common metallic materials (stainless steel, titanium, aluminum, copper, etc.).

The repeatability of the process ensures consistent quality, which is essential for semi-repetitive production.

Stability, reproducibility and quality control

For medium production runs, welding parameters are calibrated to ensure reproducibility throughout the entire production run. Robotic cells and integrated controls ensure :

- Beam and deposit stability

- Traceability of welded parts

- Significant reduction in scrap rates

By outsourcing this process to a specialist, you secure the entire production chain, from prototype to series production.

How DOUBLE CŒUR supports your medium-volume laser welding projects

At DOUBLE CŒUR, we support manufacturers in their medium-volume laser welding subcontracting needs with a technical, responsive approach. Our team is involved right from the design phase, to guarantee reliable, repeatable assembly that meets the specific requirements of your parts. Every industrial project deserves a clear, rapid and tailored response. To discuss your requirements for medium-volume laser welding subcontracting, contact us today.