Today, laser welding is an essential assembly process in modern industry. Thanks to a concentrated beam of light energy, it enables precise, clean and durable welds to be made without direct physical contact. Used in demanding sectors such as medical, automotive and aerospace, laser welding offers numerous advantages: speed, consistent quality, low thermal distortion…

In this article, find out what makes this technology so effective, how it works, on which materials it is applied, and in which contexts it is most relevant.

What is laser welding?

Laser welding is a thermal joining process involving the local fusion of two parts using a focused laser beam. The high energy density of the beam melts the edges of the materials to be joined, creating a rapid solidification weld with no mechanical contact. Unlike traditional welding methods such as TIG, MIG or arc welding, laser welding does not require an electrode. It can be carried out with or without filler metal, depending on the mechanical or aesthetic requirements of the application.

This process stands out for its extreme precision, speed of execution and ability to weld hard-to-reach areas, making it an ideal solution for technical, miniaturized or complex parts.

How does laser welding work?

Laser welding is based on a simple principle: transforming laser light energy into heat to locally melt the materials to be joined. This targeted melting, followed by rapid solidification, creates a high-strength welded joint with no mechanical contact. This process is appreciated for its precision, speed and thermal control. It is particularly well suited to industrial environments where consistent quality and reproducibility are essential.

Laser beam principle and focusing

The heart of the process is the laser beam, a concentrated energy source capable of reaching very high temperatures at a precise point. This beam is generated by a fiber laser, a disc laser or a diode laser, depending on the needs of the application.

Beam focusing is a key parameter. By adjusting the diameter of the point of impact and the depth of focus, it is possible to control :

- Weld penetration depth

- Thermally-affected zone (TAZ)

- Melting bath stability

This precise focus makes it possible to work on very thin thicknesses, to perform micro-welds, or on the contrary, to weld deep into robust metallic materials, without affecting their structure.

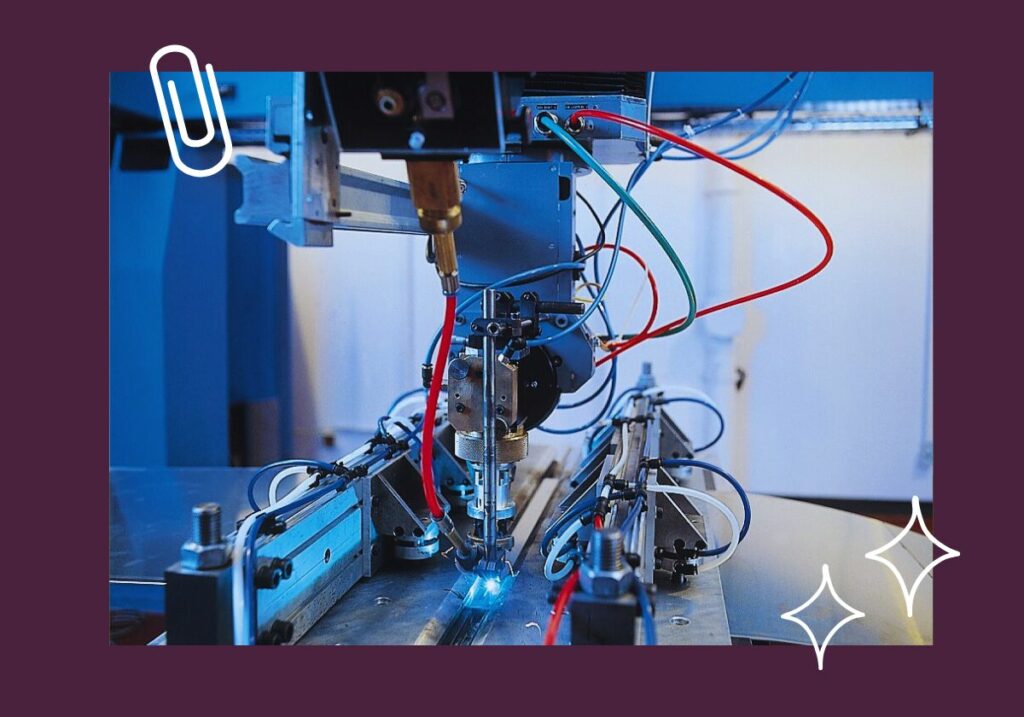

Components of a laser welding system

An industrial laser welding cell generally consists of the following components:

- A suitable laser source (fiber, diode, CO₂…) depending on the type of material to be welded

- An optical guidance and focusing system, enabling the beam to be concentrated in the right place

- An automated positioning device, such as an industrial robot or CNC table, to move parts or the welding head with precision

- A process control system (sensors, cameras, on-board software)

- A protective atmosphere (often argon or nitrogen) to prevent oxidation during melting.

The unit can be integrated into an automated welding line, guaranteeing fast, reproducible welding, perfectly suited to mass production or complex parts requiring extreme precision.

Why choose laser welding in industry?

In an environment where quality, precision and performance are essential, laser welding offers major technological advantages. It enables complex or miniaturized parts to be assembled with a high level of finish, while meeting industrial productivity requirements.

This process is particularly well suited to sectors requiring constant reliability and perfect control of thermal deformation: medical, aerospace, automotive, electronics, etc. It can be used to produce invisible welds as well as high-strength joints.

Key process benefits

Here are the main advantages of laser welding over traditional joining processes:

- Extreme precision: perfectly suited to fine, technical parts or complex geometries.

- Low heat input: limits deformation and preserves material integrity.

- Automatable: easily integrated into robotized production lines.

- High speed of execution: enables mass production with consistent quality.

- Clean welding: no contact, no spatter, excellent surface finish.

- Reduced rework costs: fewer defects, less rework, better repeatability.

What materials can be laser welded?

One of the great advantages of laser welding is its versatility. The process can be used to join a wide range of materials, both metallic and non-metallic, with a level of precision and quality difficult to achieve with other methods.

The choice of material naturally influences the type of laser used, the welding parameters, and the need for filler metal. Here are the main families of compatible materials.

Materials compatible with laser welding

Laser welding is particularly effective for joining technical metals. It produces solid, aesthetic and reliable welds on :

- Mild, stainless and galvanized steels

- Aluminium alloys, sensitive to deformation

- Titanium and its alloys, in demand in the aerospace and medical sectors

- Nickel, Inconel and other high-performance alloys

- Copper, despite its high reflectivity, thanks to high-power lasers and specific wavelengths

Laser welding is also well suited to dissimilar assemblies, for example between two different alloys, or between parts of different types and thicknesses. In this way, it can meet complex functional and mechanical requirements.

Plastics and polymers

Laser welding of plastics is based on a different principle from that of metals. It generally involves joining a laser-transparent part to an absorbent part (often colored or charged).

Under the effect of the laser, the absorbent part melts and fuses with the upper part, without contact, vibration or the need for glue.

This process is particularly used in sectors where cleanliness, tightness and assembly precision are critical, such as :

- The medical sector (housings, connectors, micro-components)

- Electronics (sensors, hulls, onboard systems)

- Or the automotive industry, especially for interior and driver assistance components

In what sectors is laser welding used?

Thanks to its technical performance and versatility, laser welding is now widely integrated in many industrial sectors. It meets the demands for precision, traceability, cleanliness and productivity in fields where assembly quality is strategic. This process is particularly well suited to the following industries:

Automotive industry

The automotive sector takes full advantage of laser welding to :

- Bodywork welding

- Electric battery assembly

- Lightweight chassis parts

- Or on-board electronic components

Its high efficiency and reproducibility make it particularly suitable for automated production lines, where speed and quality must be perfectly controlled.

Aerospace

The aerospace industry requires processes capable of :

- Welding special alloys (titanium, Inconel, etc.)

- Tight tolerances

- Guaranteeing structural integrity under extreme conditions

Laser welding enables lightweight parts to be assembled with high mechanical strength, helping to reduce weight while ensuring equipment safety.

Defense and security technologies

In defense and high-security applications, laser welding is in demand for its assembly precision and visual discretion. It is used in particular for :

- Aiming or communication components

- Protected electronic structures

- Shielding or protection elements

DOUBLE CŒUR: laser welding expertise for industrial performance

A specialist in laser processes applied to production, DOUBLE CŒUR supports manufacturers in the production of high value-added technical welds. Thanks to its in-depth expertise in laser welding, the company designs solutions tailored to the precision, reliability and production rate requirements of each sector.

Whether for prototypes, small series or production line integration, DOUBLE CŒUR relies on state-of-the-art industrial equipment and a team of experts dedicated to optimizing assemblies. Each weld is designed to meet the mechanical, thermal or functional constraints specific to the part’s end use.

Laser welding FAQs

What types of laser welding are there?

There are two main types of laser welding:

- Thermal conduction welding, used for thin parts or assemblies requiring an aesthetic weld. The laser energy is absorbed on the surface, and the fusion remains shallow.

- Deep penetration welding (or keyhole welding), where the energy is intense enough to pierce the material and create a deep weld. This mode is suitable for structural assemblies requiring high strength.

What is the maximum precision of laser welding?

Laser welding makes it possible to achieve precision in the order of tenths of a millimetre, or even better in micro-welding. This finesse is made possible by a finely focused laser beam, precise control of parameters (power, speed, focus), and automation aided by vision or sensors. This makes it the process of choice for electronic, medical and optical components.

Can a laser welding line be automated?

Yes, laser welding is particularly compatible with automation. It can be integrated into robotized cells, multi-axis CNC stations or continuous flow production lines. Thanks to the regularity of the process and the absence of contact, it enables high-speed production, with integrated quality control and optimized traceability.