Production of metal parts by industrial laser welding

Industrial laser welding for small and medium production runs

Joining metal parts by laser welding

We specialize in laser welding of industrial metal parts, in small and medium production runs. Our know-how enables us to produce reliable, reproducible, compliant assemblies right from the first part.

Thanks to our integrated industrial infrastructure and high-performance machinery, we can meet your needs with flexibility, responsiveness and traceability. We also integrate industrial validation steps to secure each project.

>> Read more

Our promise: reliable, reproducible, compliant metal assemblies right from the first part.

Your partner in laser welding, for reliable, robust production

Our expertise in industrial laser welding

Our expertise in industrial laser welding is based on rigorous control of key parameters: power, focus, welding strategy, complete traceability and structured control. This approach guarantees the manufacture of industrial metal parts with high mechanical strength, perfect weld tightness and good electrical conductivity, even for complex alloys.

We also ensure the geometric and dimensional stability of each batch, while preserving material quality, even for critical assemblies.

Our teams work on a wide variety of configurations, from precision components to the assembly of structural parts.

>> Read more

High mechanical strength

Assured electrical conductivity

Perfectly sealed welds

Guaranteed material health

Controlled dimensional stability

Constant geometric accuracy

Our results in figures

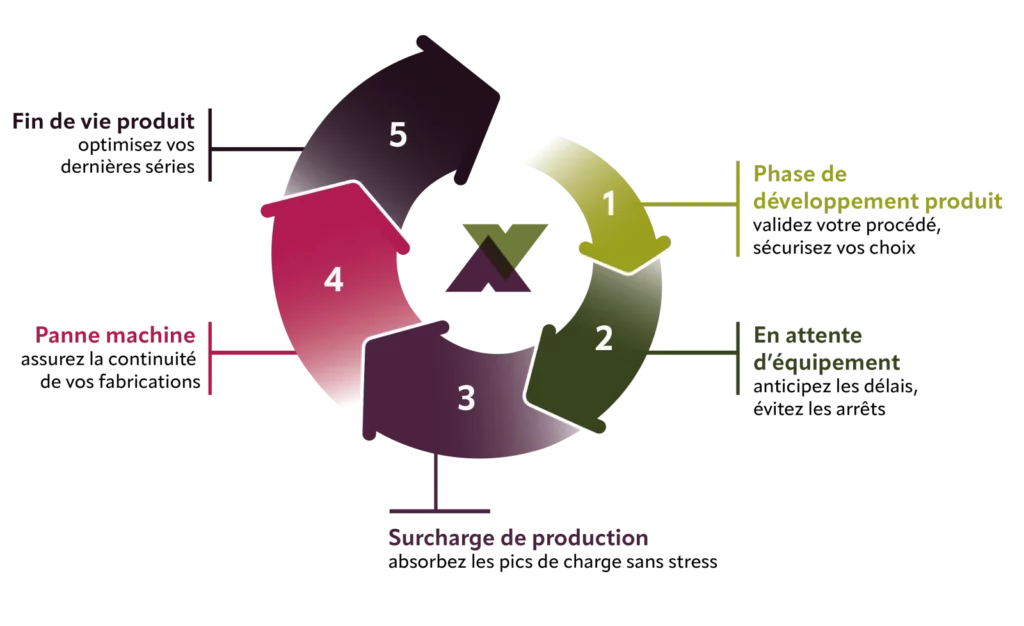

Secure your production with industrial laser welding

DOUBLE CŒUR intervenes where stability, precision and conformity are critical to the continuation of your industrial process. Thanks to our cutting-edge technologies, including laser welding, we ensure seamless production continuity, even in phases of transition, overload or uncertainty. Every part we deliver is compliant, reliable and ready for use.

1. Product development phase: validate your process, secure your choices

Are you developing a new product? We’re with you every step of the way:

- Laser welding process development

- Proof of concept (POC)

- Production of functional pre-series

The aim is to remove technical hurdles, make the process more reliable and prepare for a smooth transfer to series production.

Our industrial approach saves you time, reduces risks when ramping up, and ensures a controlled production trajectory.

2. Waiting for equipment: anticipate delays, avoid stoppages

Is your future production equipment taking too long to be delivered?

Don’t put your projects on hold. DOUBLE CŒUR takes over with production capacity that can be mobilized immediately. Based on your plans, specifications and quality requirements, we ensure smooth, reliable transitional production to avoid project stoppages.

3. Production overload: absorb peak loads without stress

Is your workshop overloaded? Peak demand? A prolonged ramp-up?

Entrust us with surplus production and stay in control:

- Consistent quality

- Compliance assured

- Deadline met

We become your industrial arm: responsive, rigorous, perfectly aligned with your standards.

4. Machine breakdown: ensure production continuity

A machine failure doesn’t have to stop your production.We provide an operational Plan B:

- Fast handling of your welds

- Uninterrupted production

- Reduced operating losses

Thanks to our agility and availability, we minimize downtime and protect your customer commitments.

5. Product end-of-life: optimize your last production runs

At the end of the cycle, volumes decrease, but the requirements remain.We take charge of your residual batches or short runs, under optimized industrial conditions:

- Maximum flexibility

- Controlled process

- Cost optimization

Free up your internal resources to focus on your future projects.

We optimize your production tool

Our experts intervene directly on your lines to remove technical bottlenecks: process adjustments, assembly robustness, laser weld reliability.

We secure your industrialization

Are you developing a new product or integrating a new process? We can support you in the development of laser welding for rapid transfer and controlled production.

We are your technical partner

DOUBLE CŒUR not only provides services, but also designs customized laser welding solutions, adapted to your most demanding industrial constraints.

Our strengths in laser-welded metal parts production

Continuous lengths: up to 5 m

Our industrial laser welding projects

Our achievements testify to our expertise in laser welding of complex, precise metal parts to industrial specifications.

Welded parts

Our production lines ensure high assembly precision, whether for thin parts just a few millimeters thick, or large structures several meters long, simple or complex, even in large volumes.

Welded materials

We produce laser-welded assemblies on a wide range of metal alloys, including the most sensitive and demanding: Steels – Stainless steels – Aluminum alloys – Copper – Nickel alloys – Titanium alloys – etc.

Each material is welded using tailor-made parameters, validated by our teams, to guarantee metallurgical integrity, mechanical strength and absence of internal/external defects.

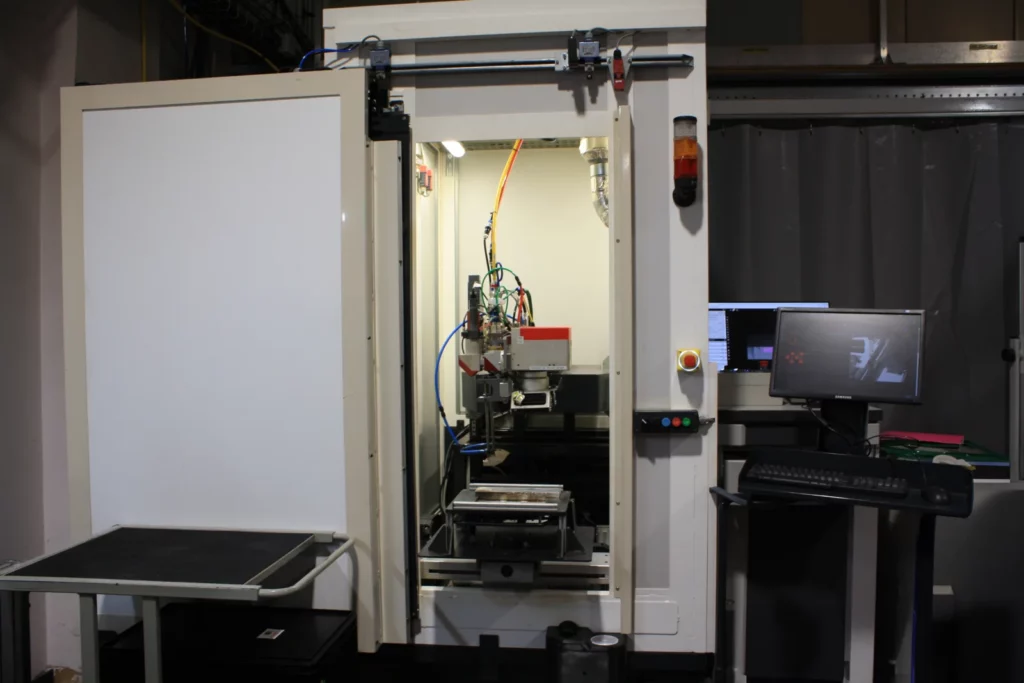

Our production facilities dedicated to industrial laser welding

Our industrial laser welding production facilities are based on a complete, integrated, high-performance infrastructure.

- Multi-configuration high-power laser machines (up to 10 kW)

- Welding robots for complex geometries

- Multi-axis workstations and vision systems

- Integrated online quality control

- On-site preparation, adjustment and post-processing

Why choose double core for your industrial laser welding production?

Expert mastery of laser welding

Compliant production from the very first piece

Integrated & high-power machine park

Reactivity industrial