Industrial additive manufacturing of metal parts

Production of metal parts using 3D laser printing

At DOUBLE CŒUR, an industrial subcontractor with expertise in additive manufacturing, we produce technical metal parts in small series or POC, using DED laser wire and DED laser powder technologies. This3D metal printing approach enables us to meet your requirements in terms of performance, complex geometry or miniaturization.

Our industrial infrastructure guarantees agile, reproducible production that complies with quality standards. Whether it’s a prototype or a ramp-up, each part benefits from a high level of traceability and perfect adaptation to your functional constraints.

Our promise: ready-to-use, compliant metal parts, produced quickly and drift-free, from prototype to production run.

Your partner in additive manufacturing, for controlled production from the very first part

Our expertise in additive manufacturing

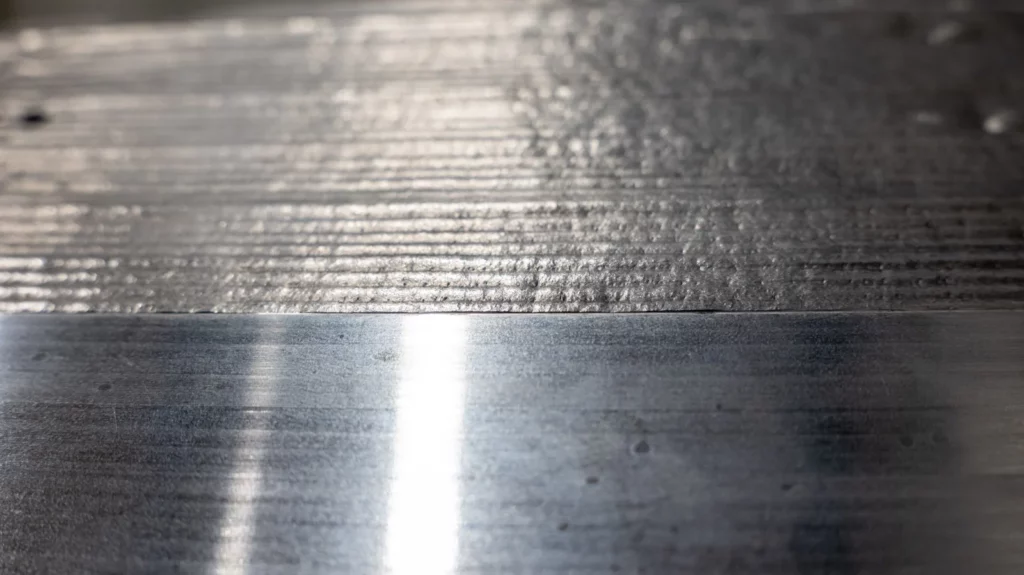

Our know-how is based on in-depth mastery of the critical parameters of industrial additive manufacturing: laser power, deposition rate, trajectory strategy, inter-pass temperature and metallurgical homogeneity. Each step is controlled to guarantee consistent, reproducible material quality.

Thanks to this rigorous approach, we produce compliant metal parts from the very first piece, with optimized material density, homogeneous microstructure and high geometric precision, even on complex shapes or sensitive materials.

We work on both one-off and small series production, from functional prototypes to large-scale metal parts.

Validated mechanical strength

High material density guaranteed

Metallurgical homogeneity preserved

Controlled dimensional stability

Guaranteed geometric accuracy

Controlled deposit regularity

Our results in figures

Secure your metal additive manufacturing production, without disruption

At DOUBLE CŒUR, metal additive manufacturing is a strategic industrial lever. From design to material deposition, we secure every stage of the process to guarantee high-performance, reliable metal parts that meet industrial requirements.

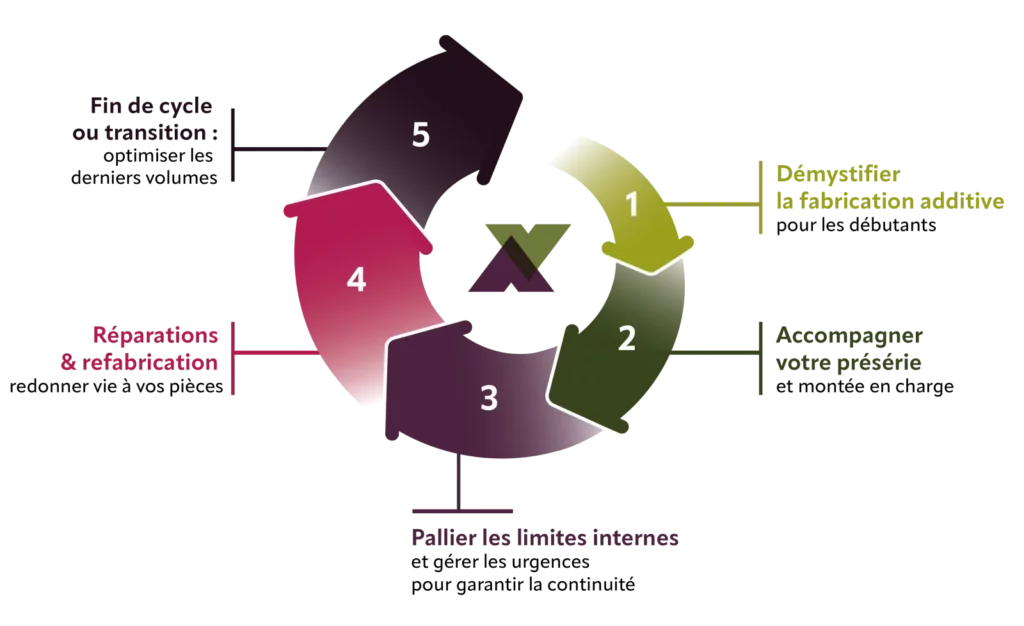

1. Demystifying additive manufacturing for beginners

Many manufacturers using conventional processes (machining, casting) want to move into metal additive manufacturing, but lack the necessary expertise. DOUBLE CŒUR can help you make the right technological and economic choices right from the start.

More than just a prototyping service, we offer a complete industrial process:

- Additive design and redesign

- Prototyping, technical validation

- Strategic consulting

Our strength: a robust industrial infrastructure and proven expertise in DED (wire & powder) processes. We transform your constraints into reliable, reproducible and profitable metal parts.

Your benefit: integrate the additive with peace of mind, with a partner who guarantees quality and profitability right from the start.

2. Support for pre-production and ramp-up

DOUBLE CŒUR ensures controlled production from pre-production through to small production runs.

- Industrial-scale validation, without heavy investment

- High-performance machinery

- Volume adaptation: reliability, stability, compliance

Your advantage: flexibility and performance to meet fluctuating production needs.

3. Overcoming internal limitations and managing emergencies to guarantee continuity

DOUBLE CŒUR responds rapidly to capacity saturation, unforeseen demand, breakdowns or maintenance to ensure continuity of your additive production.

- Fast, agile ramp-up

- Maintaining quality and rigorous traceability

- Urgent delivery of compliant parts

- Flexibility to absorb peaks without breakage

- High-performance production line without heavy investment

Your peace of mind: a continuous, high-performance chain, without excessive investment.

4. Repairs & remanufacturing: bringing your parts back to life

Additive manufacturing is ideal for repairing or refurbishing complex metal parts.

- Durable, precise solutions

- Compliance with industry standards

- Controlled costs, minimal impact on production

5. End of cycle or transition: optimizing final volumes

At the end of a production run or when a range is changed, we can take charge of your last batches.

- Making the last volumes profitable

- No need for additional in-house resources

- Respect for quality and deadlines

Your advantage: maintain your peace of mind and move ahead with new developments.

Our strengths in metal additive manufacturing

Our metal additive manufacturing products

Manufactured parts

From prototypes to structural parts several meters long, we produce custom metal components, whether complex or large-scale, with high geometric precision and excellent material quality.- Structural parts for the aeronautics, energy, naval and rail industries,

- Multi-material hybrid parts or complex geometries,

- Localized material additions or functional repairs,

- Prototypes, pre-production runs, tooling and technical components.

Materials worked

We manufacture additive parts in a wide variety of metal alloys, adapted to your performance constraints: steels – stainless steels – aluminum and aluminum bronze alloys, nickel alloys – titanium alloys – antifriction or regula alloys – cored wires – etc.

Two technologies for metal additive manufacturing

Depending on your performance, geometry or material constraints, DOUBLE CŒUR uses two complementary processes for metal additive manufacturing: DED laser wire and DED laser powder.

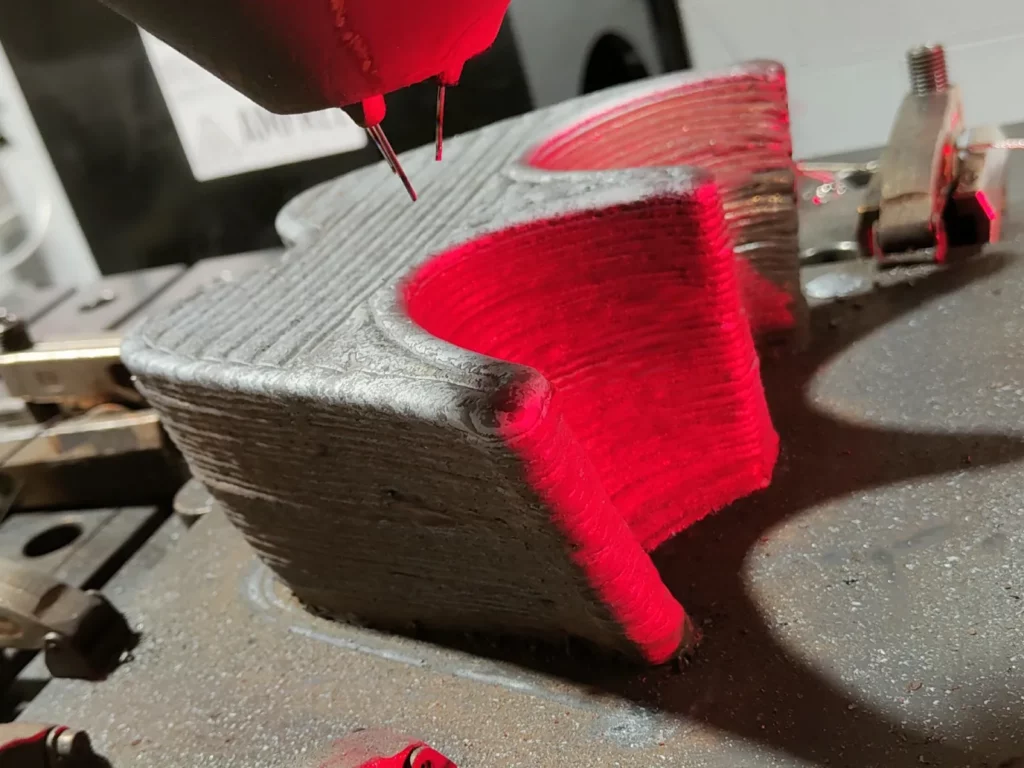

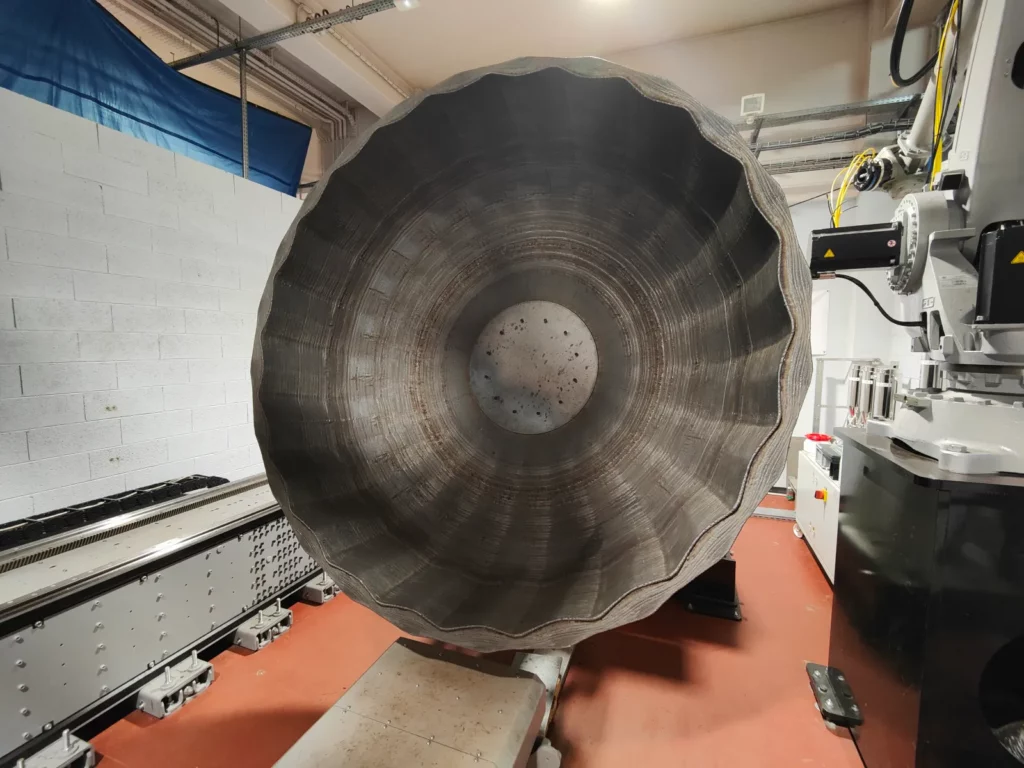

DED laser wire additive manufacturing

The industrial solution for your high-value, high-volume metal parts.

Used to produce or repair complex, large or strategic parts, with high manufacturing speed, reliable metallurgical quality and excellent material yield.

- Rapid production of large parts

- Excellent mechanical performance

- Low material losses

- Compatible with many alloys

- Fabrication, repair or localized addition

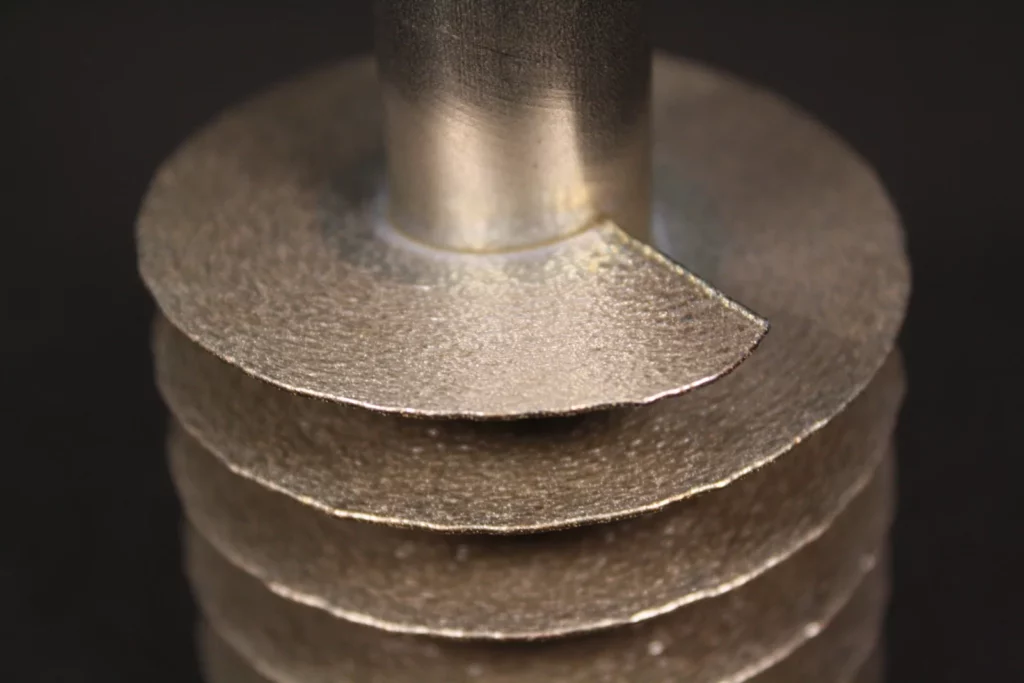

DED laser powder additive manufacturing

The industrial solution for your high-precision metal parts.

Used to produce or repair thin, complex or multi-material parts, with extreme precision, excellent surface quality and great geometric freedom.

- High-precision depositing for complex areas

- Optimized finish, minimal post-processing

- Compatible with critical alloys (Inconel, titanium...)

- Ideal for thin geometries and thin walls

- Targeted manufacture, modification or repair

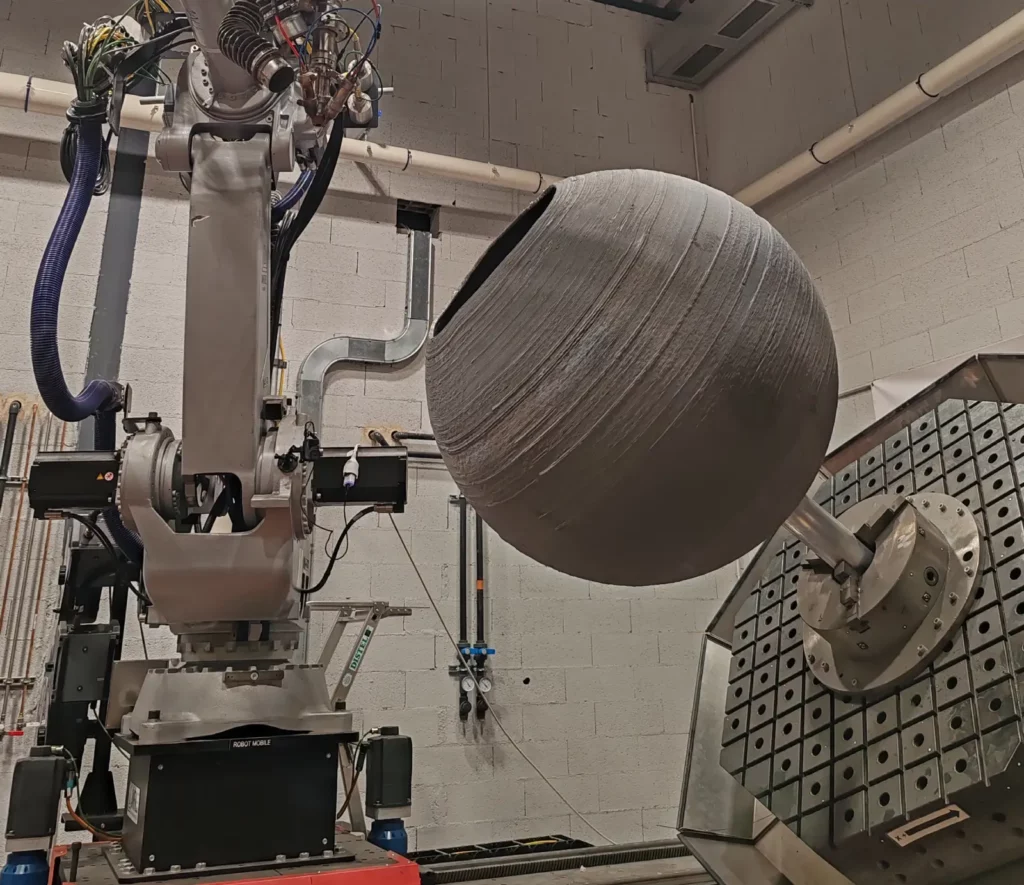

Large-format metal additive manufacturing

At DOUBLE CŒUR, we support manufacturers faced with the technical challenges of large-scale metal additive manufacturing.

We produce parts of up to 5 meters and 30 m³, with consistent metallurgical quality, controlled geometric precision and perfect functional conformity.

Thanks to our expertise in custom manufacturing, we ensure rigorous control, integrated quality control and optimum repeatability, even for complex geometries.

Our commitment: to transform your ambitious projects into ready-to-use parts, without compromising on quality, deadlines or performance.

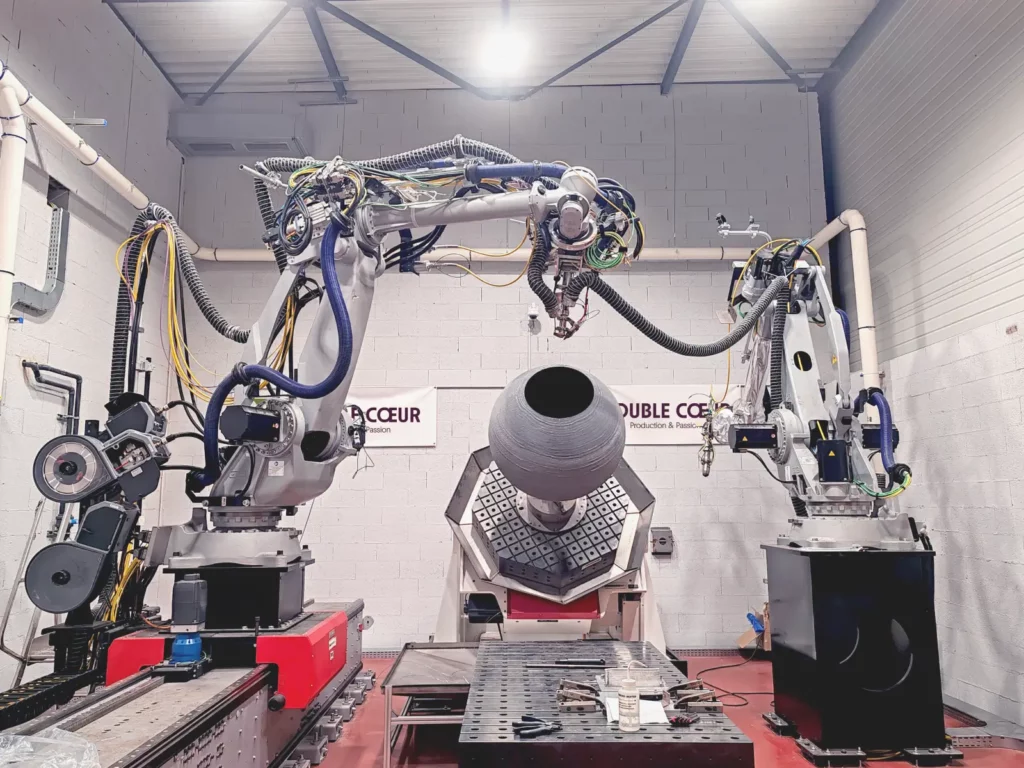

Our dedicated metal additive manufacturing infrastructure

Our metal additive manufacturing workshop is supported by a complete industrial infrastructure, designed to meet the production requirements of complex metal parts, from small series to large formats.

We use state-of-the-art wire and powder laser DED processes, high-power laser sources, robotized deposition heads and advanced control systems. This integrated chain enables us to guarantee reliable, repeatable and compliant additive manufacturing, even on sensitive alloys.

Thanks to this technical mastery of metal 3D printing, we can produce metal parts up to 5 meters long or 30 m³ in volume, while ensuring a high level of quality at every stage of the process.

Why choose double core for your additive production?

DED laser wire and powder expertise: two complementary technologies

Industrial flexibility: we're there every step of the way

Validated quality, right from the first part: rigorous integrated controls

Project agility: a structured, flexible and responsive organization