About us

Subcontractor in laser welding and metal additive manufacturing

At DOUBLE CŒUR, we specialize in the manufacture of technical metal parts by laser welding and metal additive manufacturing (3D metal printing). We produce small and medium-sized runs for industrial customers looking for reliability, precision and performance.

With over 40 years’ experience, we are recognized for our technical expertise, industrial agility and quality culture. Our customers come from the most demanding sectors: aeronautics, automotive, space, energy and e-mobility.

Our commitment: get it right first time

We manufacture robust, precise and compliant parts, right from the first unit, in a wide variety of materials: aluminum, titanium, stainless steel, copper, Inconel, etc.

Each project is carried out with operational rigor to guarantee :

- Perfect repeatability

- Strict compliance with specifications

- Total control over deadlines and costs

Our mission: securing your critical production

We provide industrial support to ensure the continuity of your production in sensitive situations:

- Arrival or delay of new equipment

- Machine overload or downtime

- Scale-up or end of product life

Our integrated organization, designed for efficiency and responsiveness, offers you reliable, flexible and immediately operational support.

Our commitment: certified industrial quality

ISO 9001:2015 certified, we are also committed to producing metal parts in strict compliance with the most stringent quality standards, including those in force in the aerospace, automotive, energy and e-mobility industries.

Each part is manufactured under complete quality control, with constant attention to dimensional accuracy, mechanical strength, production stability and documentary conformity, among other things.

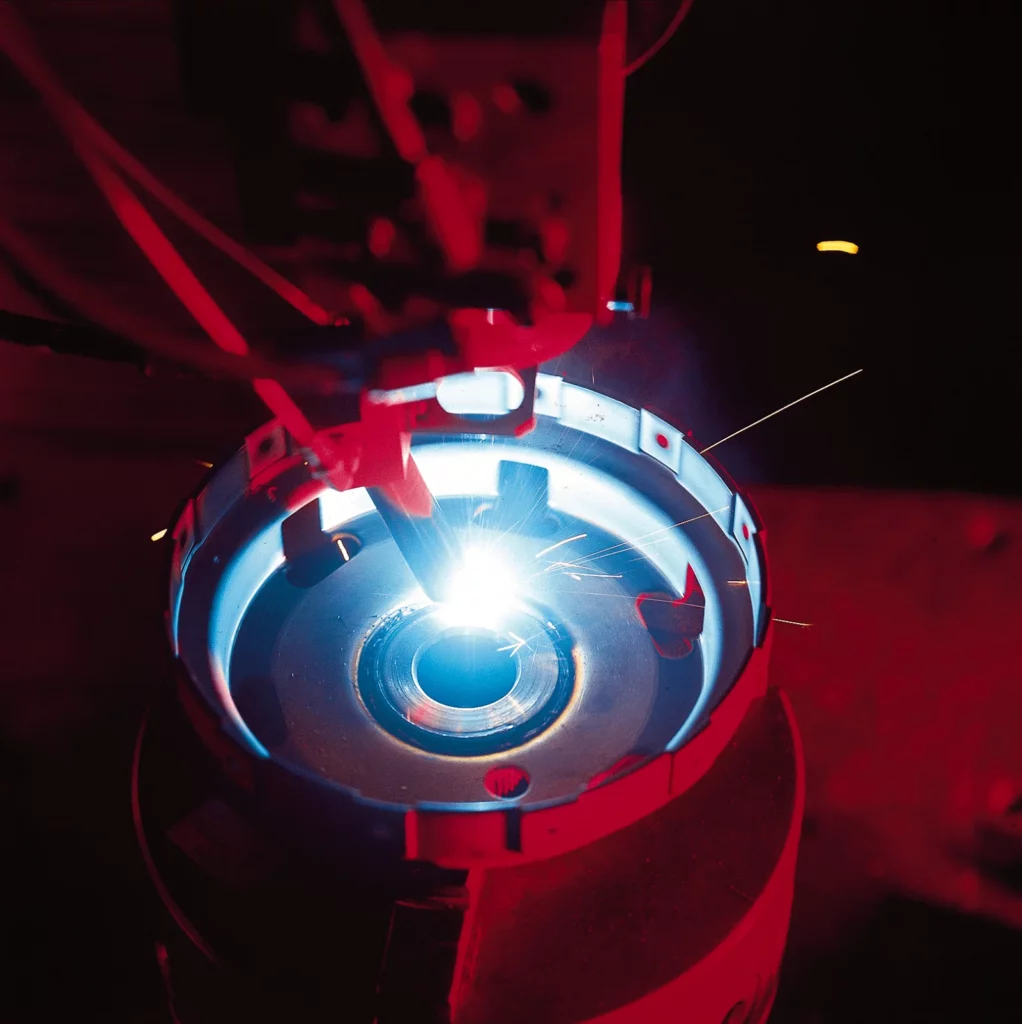

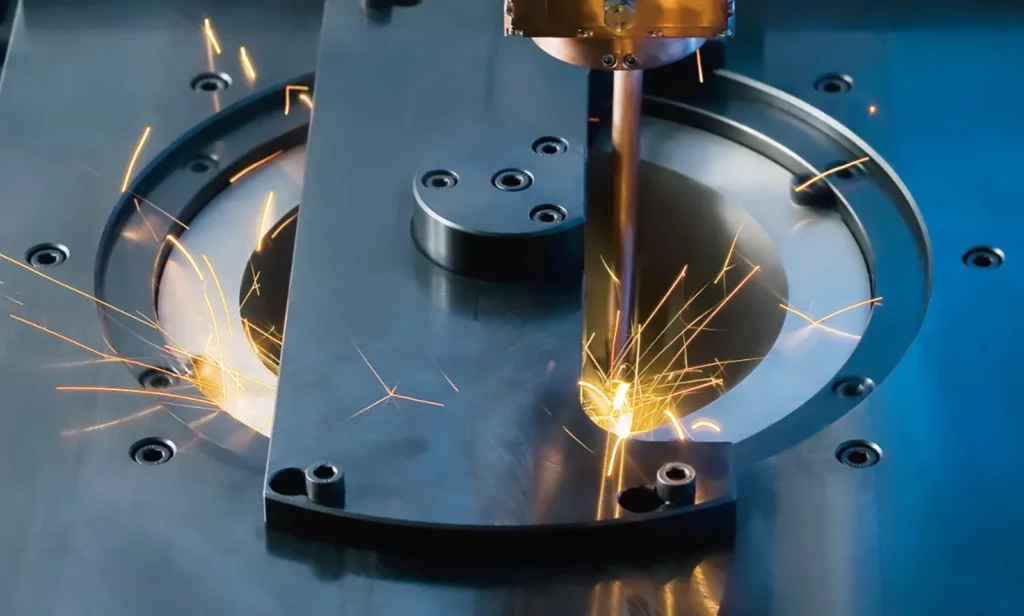

Precision laser welding for reliable, durable industrial assemblies

At DOUBLE CŒUR, our expertise in industrial laser welding guarantees extremely precise metal assemblies, with reliable mechanical resistance and optimum production stability.

Thanks to our mastery of critical process parameters, we can weld parts from a few millimeters to several meters, in small or medium production runs, on a variety of materials such as aluminum, copper or specific alloys.

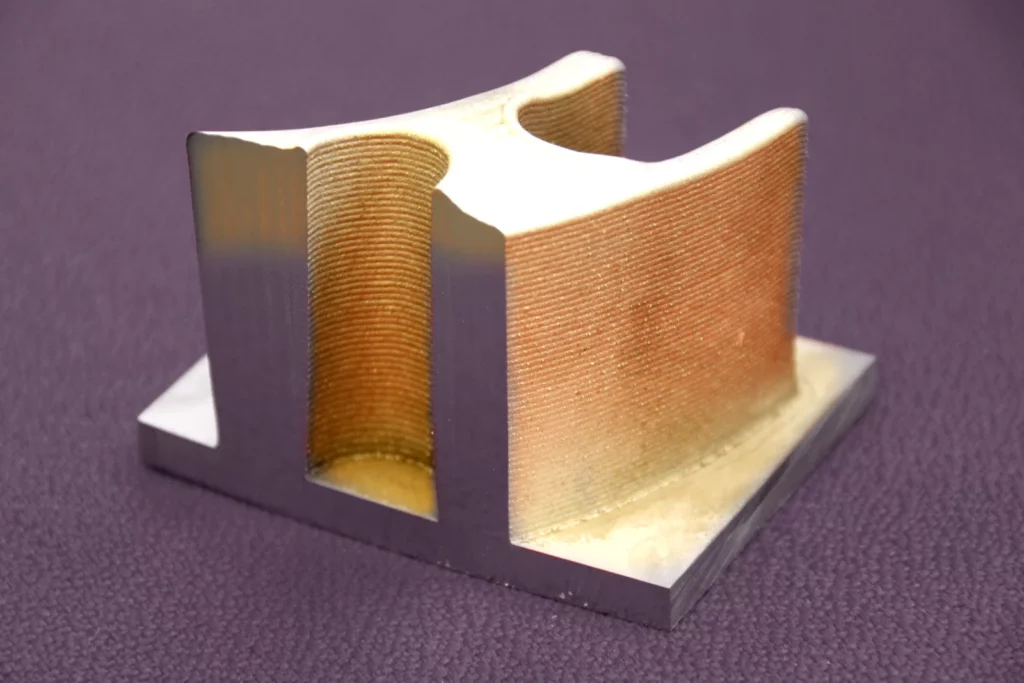

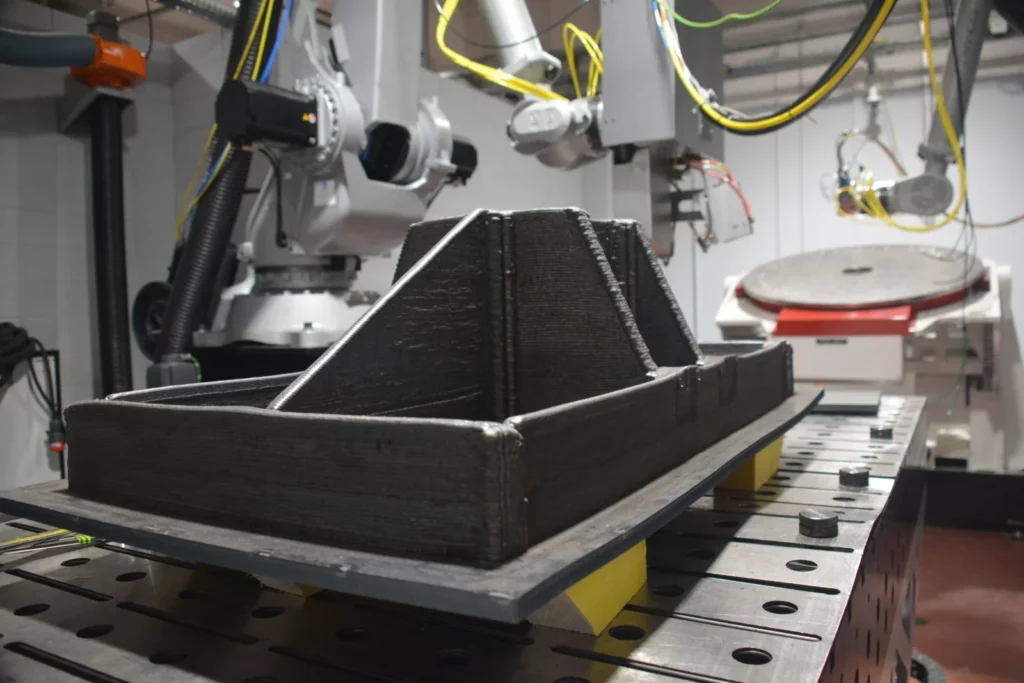

Metal additive manufacturing: fast, precise and compliant production

At DOUBLE CŒUR, metal additive manufacturing enables us to produce technical parts that are right the first time, without rework or adjustment.

Thanks to DED laser wire and powder processes, we can guarantee high geometric precision, consistent material quality and controlled functional performance, even on complex or large geometries.

From prototype to small series, we meet the most stringent industrial requirements.

Sectors of intervention

Our expertise is applied in industrial environments where performance cannot be compromised

Aeronautics

Spatial

Nuclear

Energy

Automotive

Rail

E-mobility

Defense

A team of experts in laser welding and additive manufacturing

Our employees – process engineers, laser technicians, operators and project managers – work hand in hand to transform your needs into concrete industrial solutions.

Their expertise is based on proven processes, rigorous quality control and active listening to your challenges.

Continuously trained to master laser welding and metal additive manufacturing processes by theIREPA LASER training center, our teams maintain a high level of competence, in line with the latest technological innovations.

Responsive and committed, we tailor our support to each project to guarantee reliable, rapid and customized solutions.

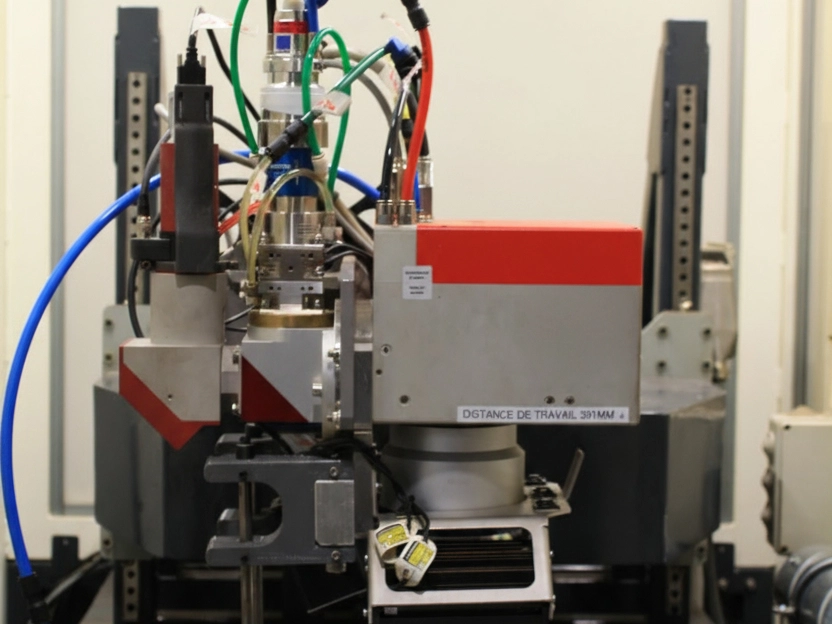

An industrial infrastructure designed for additive manufacturing and laser welding

Our state-of-the-art industrial equipment covers all laser welding and metal additive manufacturing processes. High power, robotization, integrated control… each piece of equipment is designed to guarantee precision, reliability and industrial performance.

This advanced industrial infrastructure enables us to carry out high-precision laser welding operations on parts of all sizes, even complex ones, while ensuring excellent mechanical resistance. In addition, we use DED (laser wire and laser powder) additive manufacturing technologies to meet specific geometric and material requirements in the most demanding sectors.

Why choose double cœur for your industrial metal parts production?

Quality assured from the 1st part, consistent, repeatable production

Reactivity and flexibility, even in emergency situations

Specialist in laser welding and metal additive manufacturing

Agile production to secure your industrial flows

High quality, traceability and compliance with standards

Location of our sites

Production site

DOUBLE COEUR

320 Boulevard Sébastien Brant

67400 Illkirch-Graffenstaden

France

+33 (0)3 88 65 54 00

Head office

IREPA LASER

Parc d’innovation

67400 Illkirch-Graffenstaden

France

+33 (0)3 88 65 54 00

Expertise inherited from IREPA LASER, for mass production

DOUBLE COEUR was born withinIREPA LASER, a reference center for laser technologies for over 40 years. As the projects progressed, it became clear that manufacturers needed a partner capable of producing, not just designing.

From R&D to production

DOUBLE COEUR was created to take action, with a simple mission: to produce, assemble and deliver complex metal parts, in industrial series, with the same high standards as in the standardized sectors.

We are an industrial division specializing in the production of metal parts using high-precision laser welding and metal additive manufacturing (DED laser wire and powder).

Why do our customers choose us?

- A performance-oriented organization: quality, costs, deadlines

- An integrated industrial infrastructure designed for series production

- Rigorous management, with dedicated contacts

- Guaranteed control of laser processes

DOUBLE COEUR builds on the solid foundations ofIREPA LASER:

- Unique technological expertise in laser processes and metallurgy,

- High-level industrial equipment,

- A culture of co-construction with the customer, where engineers, operators and project managers work hand in hand.

Each project is carried out with a clear industrial vision:

- Continuity of production,

- Zero breakage,

- Performance optimization.

We work wherever precision, repeatability and functional reliability are essential:

- Laser welding of sensitive alloys: aluminum, copper, Inconel, etc,

- DED additive manufacturing (wire or powder) : POC, pre-series, series,

- Complex metal assemblies: conductive, sealed, robust parts,

- Accelerated transition from prototype to production run.

At DOUBLE COEUR, we don’t do marketing:

- We produce,

- We deliver,

- We keep our promises.

Every part we deliver reflects our vision of the business: reliability, rigor, responsiveness.

It’s this hands-on, committed approach that sets us apart.