Production of industrial metal parts

Specialized industrial subcontracting for small and medium production runs

Your production partner for metal parts

Over 40 years' experience

Cutting-edge expertise and proven mastery of laser processes in demanding industrial sectors.

Guaranteed production continuity

An integrated organization and industrial agility to respond quickly and secure your production chain.

ISO 9001:2015 certified

DOUBLE COEUR manufactures to quality standards in the automotive, aerospace, energy and e-mobility sectors.

Manufacturer of industrial metal parts

Laser welding & metal additive manufacturing

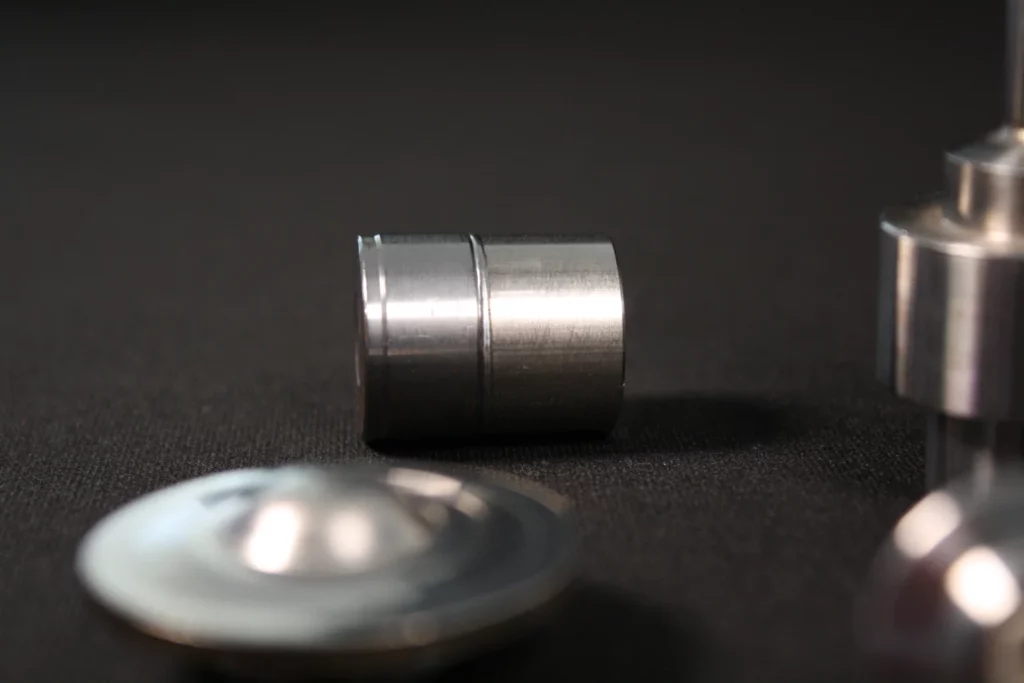

DOUBLE COEUR is your partner for the production of industrial metal parts, specializing in industrial subcontracting. We manufacture reliable, high-quality metal parts, particularly for small and medium-sized production runs. We use state-of-the-art processes such as laser welding and metal additive manufacturing (3D metal printing).

Our agility and responsiveness ensure production continuity, even in the most critical phases, for the most demanding industrial sectors.

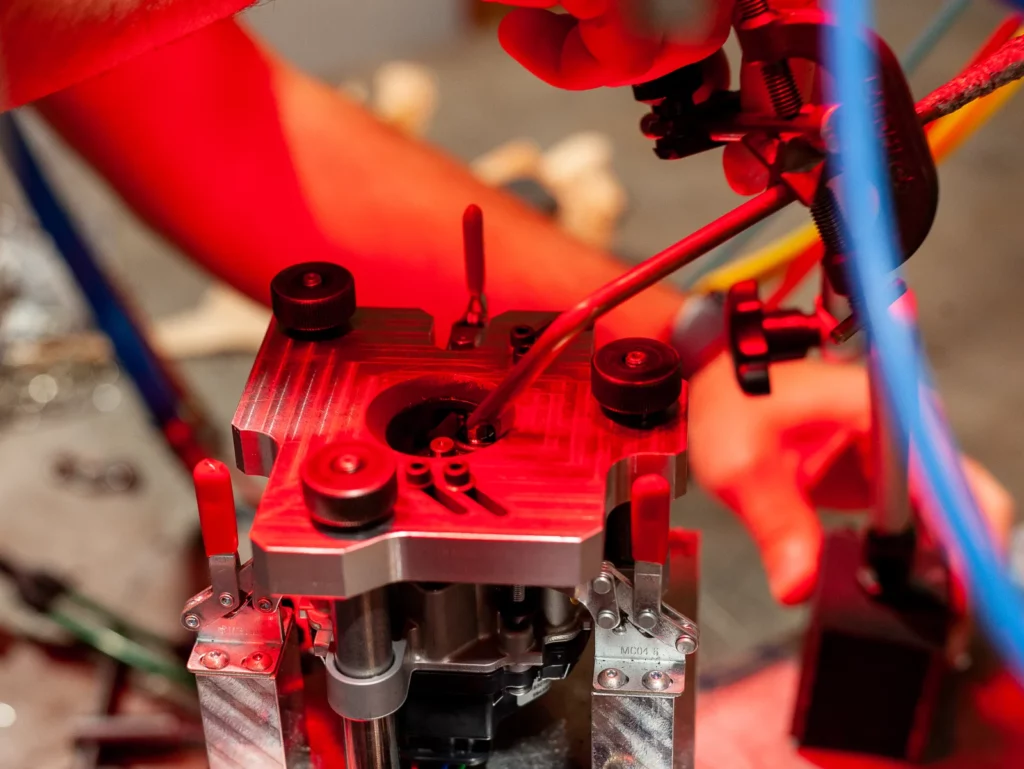

Laser welding for industrial parts production

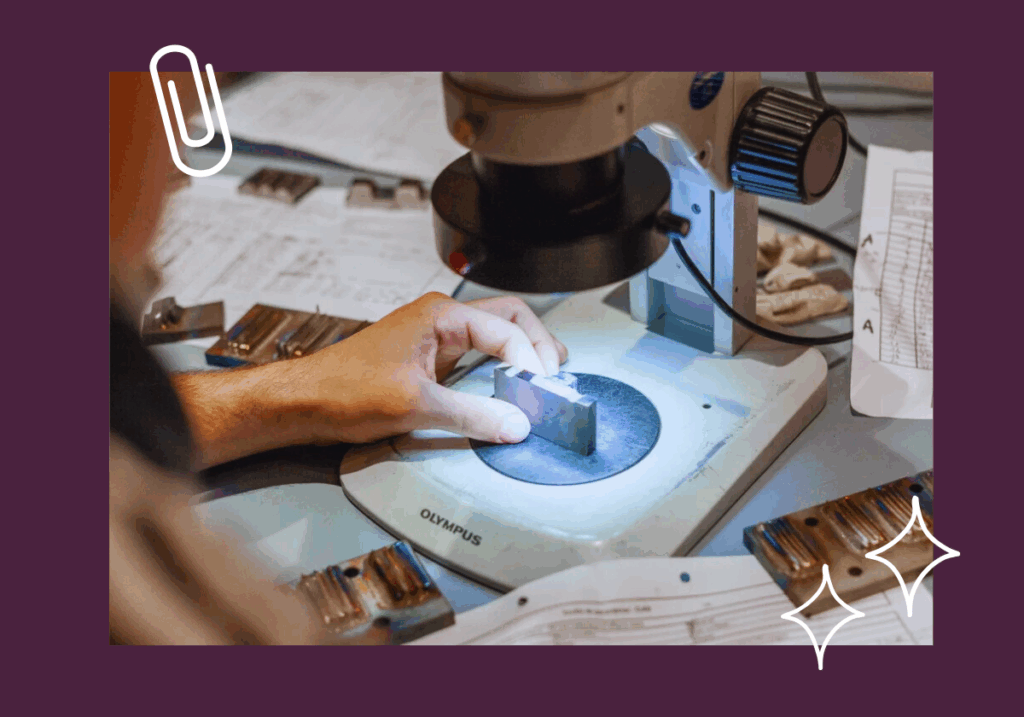

DOUBLE COEUR provides laser welding of custom-made metal parts, in small and medium production runs, with high precision and perfect mastery of technical constraints. Our processes guarantee reliable, durable assemblies that meet industrial requirements in terms of mechanical strength, tightness and conductivity.

Thanks to our high-performance machinery (lasers up to 10 kW) and recognized expertise in a wide range of materials (aluminum, stainless steel, copper, special steels, etc.), we can work on parts ranging from a few millimeters to several meters.

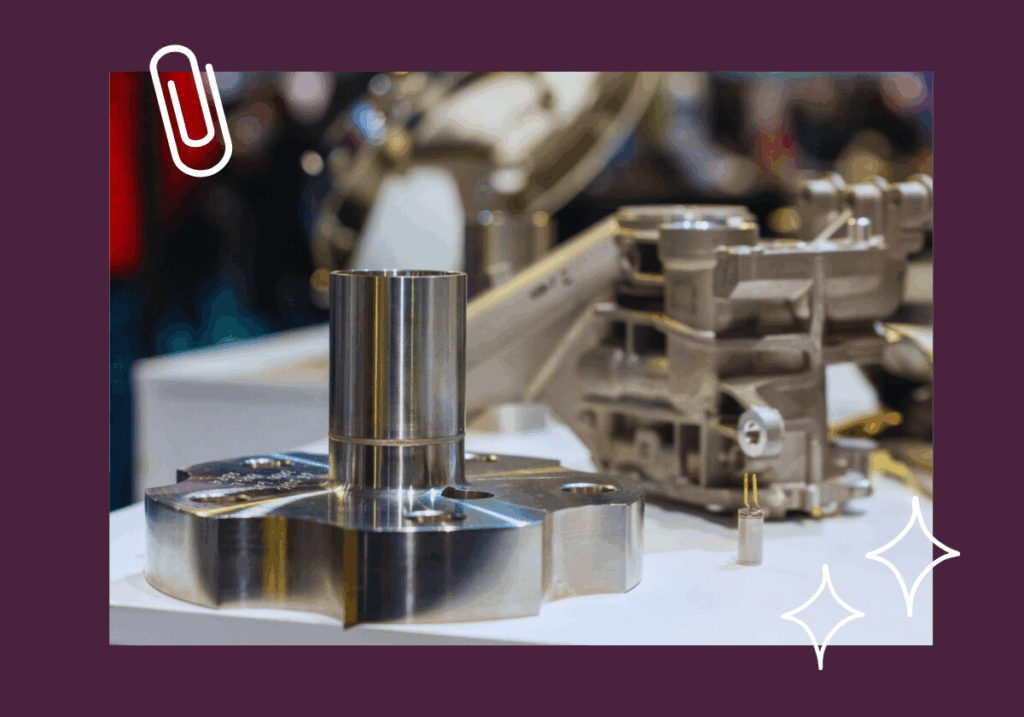

Metal additive manufacturing for the production of industrial parts

We design and manufacture metal parts by additive manufacturing, from POC to small series. We integrate your needs for geometric precision, material quality and functional performance right from the design phase. We use wire laser DED technologies for large, high value-added parts, and powder laser DED for complex, miniaturized or geometrically precise components, adapted to the functional constraints of industrial environments.

Our lasers up to 10 kW can produce parts up to 5 m or 30 m³, in a wide range of materials: aluminum, titanium, inconel, stainless steels, etc. Our expertise in process/material hybridization paves the way for innovative, tailor-made solutions.

Our results in figures

Sectors of intervention

Our expertise is applied in industrial environments where performance cannot be compromised

Aeronautics

Spatial

Nuclear

Energy

Automotive

Rail

E-mobility

Defense

Our equipment for the production of industrial metal parts

Our industrial infrastructure includes high-power lasers (up to 10 kW), DED wire and powder laser technologies, robotized cells, multi-axis workstations and advanced control systems.

Thanks to our comprehensive, modern and structured machine park, we cover all laser welding and metal additive manufacturing processes. We produce customized, specific, large or complex metal parts, in volumes ranging from a few millimeters to several meters, in a wide variety of materials (aluminum, stainless steel, titanium, special steels, etc.).

Why choose double cœur for your industrial metal parts production?

Quality assured from the 1st part, consistent, repeatable production

Reactivity and flexibility, even in emergency situations

Specialist in laser welding and metal additive manufacturing

Agile production to secure your industrial flows

High quality, traceability and compliance with standards